Table of Contents

Procurement Barrier" Looming for Shipbuilding Repairs

In shipbuilding repair and refurbishment, procurement of a wide variety of small-quantity components and large steel structures frequently occurs. However, if the procurement department is not adequately structured or if the process is field-dependent, the following issues are likely to arise.

Issues that tend to arise

- Limited number of suppliers who can handle special processing such as 3D bending and welding of thick plates

- Older parts for which drawings do not exist, and the burden of designing, scanning, and CADing for physical matching is high

- Repair projects must be completed in a short period of time, and pressure to shorten lead times has become the norm.

In the past, the staff in charge of the project had to find subcontractors on their own or create drawings by matching the actual products.

However, this takes time to search, and there are limits to the risks associated with human resources and the flexibility to respond to projects with short deadlines.

- Lack of subcontractors capable of handling special processing

- Increased design and drawing workload

- Lead-time compression for on-time delivery

- Dependence on field personnel and reduced operational efficiency

These issues and problems can be solved with Taiga.

For more information about Taiga, click here.New Procurement Solutions from Taiga

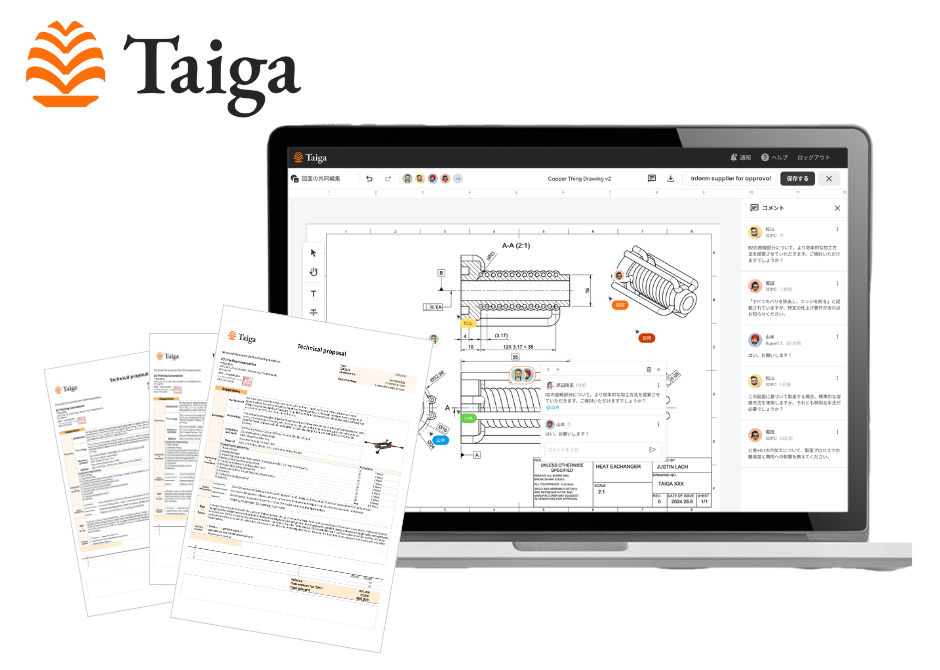

Taigais a digital platform built to solve procurement challenges in the manufacturing industry. It also solves procurement problems in shipbuilding repair and refurbishment sites.

Taiga Features

1. immediate matching of suppliers for special processing

Quickly find subcontractors that can handle 3D bending and welding of thick plates.

2. design support and drawing sharing

Design support from 3D scans and simple data, and CAD drawings can be shared.

(3) Immediate response to projects with short deadlines

The "Ready-to-Respond Supplier" shortens lead time.

4. small lot production

Since we can manufacture from a single item, orders can be placed without the risk of holding inventory.

5. structuring of procurement operations

The system is easy for anyone to use, and RFQs, quote comparisons, and orders can be completed consistently online.

What Taiga can do for you

The following improvements have been achieved at sites where Taiga has been implemented.

- Reduced lead time from 2 months to 2 weeks

- Reduction of design man-hours and improvement of accuracy (cost reduction)

- Increased on-time delivery rate

- Supply chain development to break away from gerrymandering and stabilize operations.

Flow of Utilization

1) Upload drawings and scanned data to Taiga

(2) Obtain quotes and proposals from multiple special processing suppliers

(3) Confirm specifications and request revisions using the chat function

(4) Centralized management on the Taiga from order placement to delivery and visualization of lead times

For more information about Taiga, click here.Case Study:Marine propellers(at sentence-end, falling tone) indicates a confident conclusionmanufacture

Item:Marine propellers

Dimensions: 600 mm dia., 250 mm Weight: 12.1 kg

Material: SUS 316L

Manufacturing method: metal 3D printing (DED method)

Formation time: 43 hours 40 minutes

Conventional manufacturing: Casting → Machining and polishing

After casting the parts, machining and polishing post-processing was required to meet the requirements of the marine industry, which made manufacturing time-consuming and costly.

↓arrow (mark or symbol)

Changed manufacturing method to metal 3D printing

The DED method of metal 3D printing has made it possible to reduce post-processing time and costs.

Summary

Procurement in shipbuilding repair tends to be burdened with "searching," "drawing up drawings," and "meeting deadlines.

By using Taiga, these can be structured, and an environment can be created in which even on-site personnel can proceed with procurement efficiently.

Why don't you first try Taiga on a familiar project and experience a new form of procurement?

0120-987-742

0120-987-742