Alex (Interviewer): Thank you for taking the time today, Mr. Oba. To start, could you tell us how you first joined Sayama Mold Manufacturing?

My grandfather founded the company 60 years ago, and my father served as CEO for more than 25 years. I actually joined the company in 2011 after graduating from university in the U.S. Initially, I wanted to work in America, but my father was focused on expanding our business. Initially, I wanted to work in America, but my father was focused on expanding our business internationally. That vision really drew me in.

Alex: Growing up, did you always imagine you'd eventually lead the company?

Mr. Oba: Honestly, I tried not to think about it too much. My father was always busy, but I saw how energized he was by the work-it wasn't exhausting for him, it was exciting. That made me curious.

Alex: Now that you're leading the company, what's your unique mission for the next generation?

I saw that overseas, many companies were searching for micro-precision technologies. That's where we can make a real difference.

Alex: Many companies talk about high precision. how does Sayama Mold manufacturing stand out?

We control dimensions within ±1 micrometer-beyond the ±2-3 micron specs of standard machines. It's not easy, but by continuously pushing and never giving up, we achieve it.

Our facility also plays a big role: temperature-controlled at 24°C within ±1°C, vibration-isolated, and designed specifically for precision manufacturing. precision manufacturing.

Using a rotating grinding wheel, parts are ground to a level of 1/1000 millimeter. Grinding is an essential process for achieving micron-level precision. .

Alex: That persistence must come from the people here.

Skill is important, but passion matters more. we make products no one has made before-there's no manual-so we rely on trial and error. -You need to love creating and working with machines. One example is a mold with 260 micro-channels that required two months of hand-polishing to achieve a mirror finish.

Mr. Oba: Looking forward, which markets are you focusing on?

Oba: The medical field is growing quickly-especially surgical devices and microfluidics, where components are getting smaller and more complex. We've been exhibiting at the MD&M show in the U.S. for over six years, connecting with medtech innovators.

Alex: Does working with medical startups present unique challenges?

Many startups have only a concept, so we support them through prototyping, design, and production. We also collaborate with partners to offer complete solutions, not just single components.

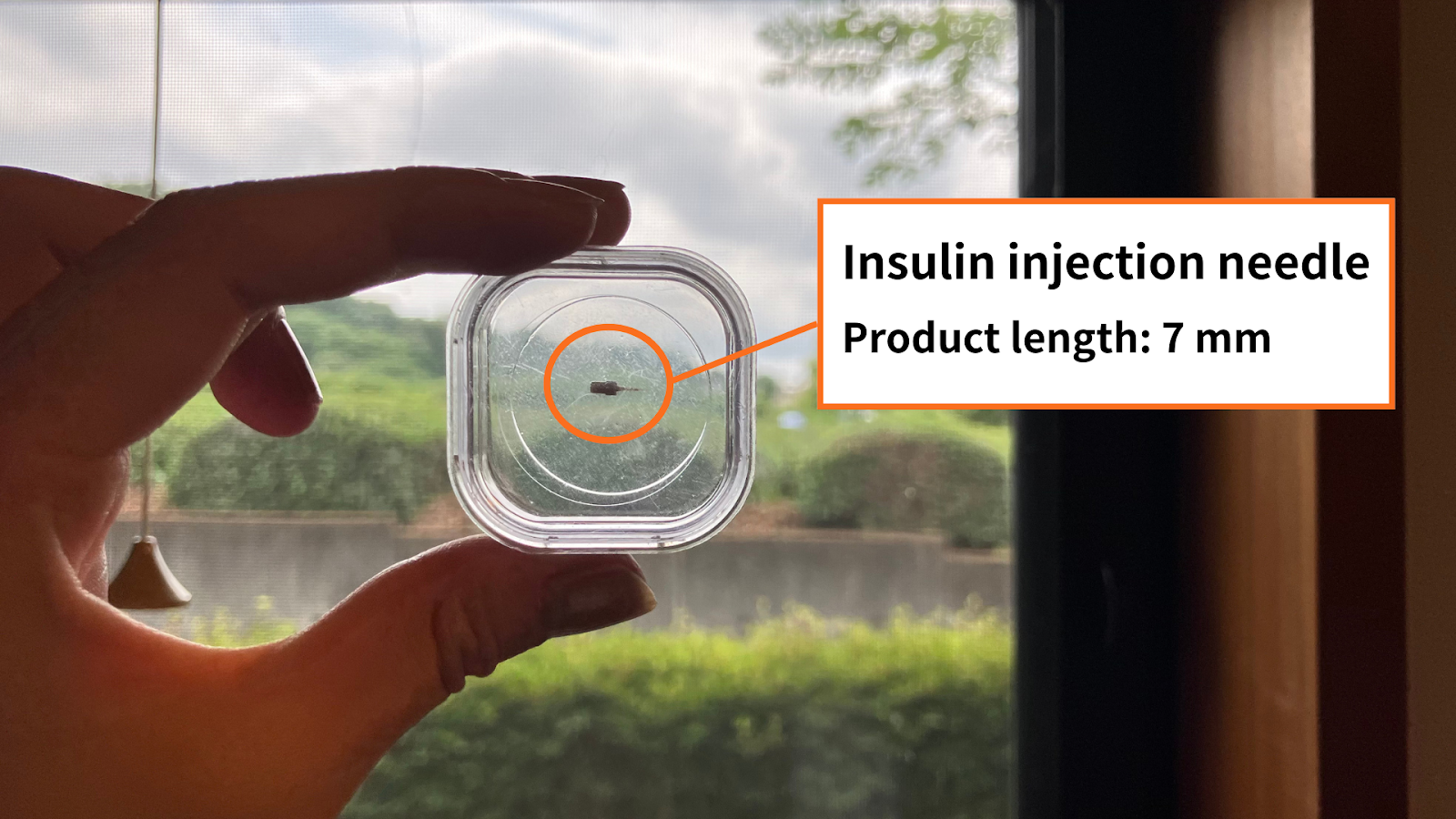

Alex: What's a product you're particularly proud of?

It has a diameter of just 0.24 mm, with holes as small as 0.07 mm. We applied our experience from semiconductor and electronics molds to succeed.

The fine 30-34G gauge smoothly penetrates the subcutaneous tissue, reducing pain and subcutaneous bleeding. It minimizes the risk of accidental intramuscular injection, enhancing safety.

Alex: How do you show clients such fine details?

Mr. Oba: We bring microscopes to exhibitions so visitors can see features that are invisible to the naked eye.

Alex: Finally, what message would you like to share with an international audience?

Mr. Oba: Sayama Mold manufacturing specializes in micro-precision with ±1 μm accuracy-a level few can achieve. I'd like to meet more people, understand their challenges, and work together to solve I'd like to meet more people, understand their challenges, and work together to solve them.

In order to satisfy its commitment to professionalism, Sayama Mold Manufacturing Co. in a location surrounded by rich natural hills.

In mold manufacturing, which requires submicron precision, even the vibration of passing cars can affect the manufacturing process.

In order to satisfy its commitment to professionalism, Sayama Mold Manufacturing Co. in a location surrounded by rich natural hills.

0120-987-742

0120-987-742