Sandwich panels made of CFRP are attracting attention as a cutting-edge composite material in aerospace and other industries requiring advanced technology.

Its lightweight and rigid properties will likely continue to be utilized in the future, greatly enhancing the performance of the product.

This article details important information that designers need to know, from basic CFRP sandwich panel construction to the latest trends.

In addition, we will provide other useful information for product development, such as manufacturing technology, selection points, and the potential of CFRP sandwich panels.

For more information about Taiga, click here.Table of Contents

What is a sandwich panel?

Sandwich panels are lightweight, high-strength panel materials with a lightweight core material sandwiched between two thin surface materials (skin material).

CFRP sandwich panels use foam or honeycomb structure as the core material between surface materials made of carbon fiber and resin.

In particular, those with a honeycomb structure for the core material are called "honeycomb sandwich," which can further reduce weight and increase strength.

Currently, honeycomb sandwich panels with aluminum honeycomb as the core material and CFRP as the surface material are widely used in artificial satellites and aircraft airframes.

The main advantages of sandwich construction are higher rigidity per weight, better heat and sound insulation, and lower manufacturing costs.

Due to these characteristics, it is widely used in various fields including the aerospace industry.

Scenes in which CFRP sandwich panels are used

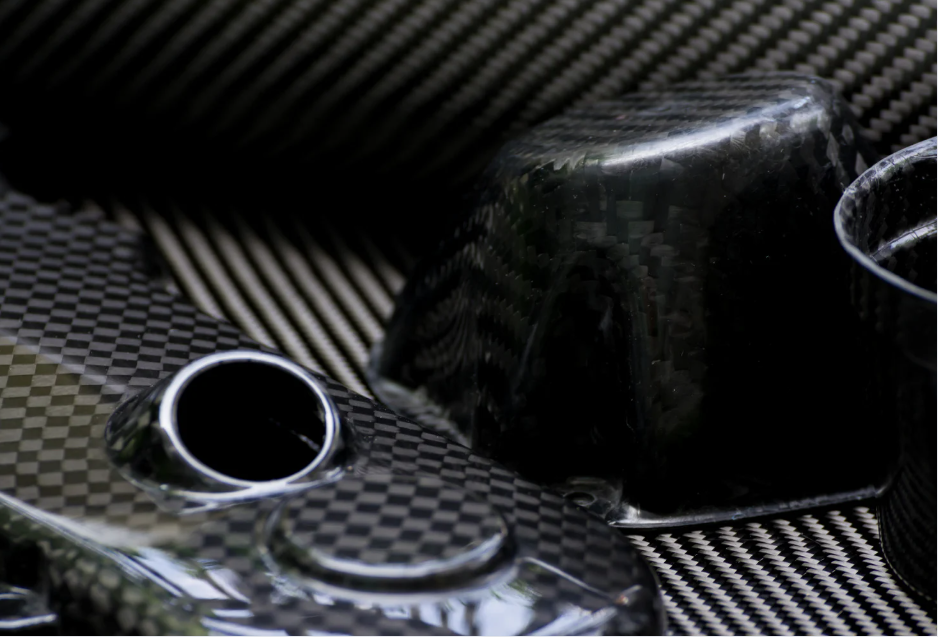

Typical applications for CFRP sandwich panels include structural materials for satellites and aircraft in the aerospace sector.

Its light weight and high rigidity make it particularly suited to the high loads at launch and the harsh environment of space.

It is also used in racing cars for body and interior/exterior parts, and as a material to enhance aerodynamic performance and safety at high speeds.

In sporting goods, it is utilized in tennis rackets, etc., and its advantage is that it reduces weight and improves the feel of hitting the ball.

Other diverse applications include drones, high-speed ships, and solar cars in schools and research institutes.

Why CFRP is used for sandwich panels

CFRP sandwich panels are used in many industrial sectors due to their excellent physical properties.

In particular, CFRP's strength in terms of light weight and high durability and rigidity are the main reasons why it is used in sandwich panels.

Let's take a closer look below.

Components can be made lighter

The greatest advantage of using CFRP for sandwich panels is its superior light weight.

The high specific strength of CFRP allows for a significant weight reduction compared to metal materials of equivalent strength.

Further improving lightweight performance is the sandwich structure, in which a lightweight core material is sandwiched between two thin, high-strength skin materials and bonded together.

For example, in the aerospace field, the adoption of CFRP sandwich panels is being actively promoted because the reduction of airframe weight directly leads to improved fuel efficiency and increased payload capacity.

In satellites, it also contributes significantly to reducing launch costs and improving operational efficiency.

High durability and rigidity

CFRP is characterized by its superior durability and rigidity, surpassing metal materials due to the combination of the high tensile strength of carbon fiber and the stability of the resin matrix.

Furthermore, CFRP sandwich panel construction greatly increases bending rigidity and resistance to vibration and shock.

In addition, its superior fatigue characteristics and high reliability in long-term use have also contributed to its adoption.

These characteristics allow CFRP sandwich panels to maintain their performance in harsh environments, such as space environments.

What is required for the manufacture of sandwich panelen using CFRP

The manufacture of CFRP sandwich panels requires a high level of expertise, precision processing techniques, and process control.

For example, from the selection of appropriate carbon fiber and resin, to advanced molding techniques such as autoclave molding, and advanced bonding techniques with core materials, etc. are required.

When hiring a contractor, in addition to technical capabilities, check for quality control systems, past performance, and research and development capabilities.

Especially in the aerospace field, it is required to meet strict certification standards such as JIS Q 9100:2004.

Latest Trends in CFRP Sandwich Panels

In recent years, CFRP sandwich panels have undergone technological innovation, with the latest trend being the development of panels with superior heat resistance.

In addition to conventional light weight and dimensional stability, satellites that observe planets in the inner solar system require heat resistance of 250°C or higher.

CFRP, a newly developed material in recent years, uses polyimide resin with excellent heat resistance to maintain stable properties even in high-temperature environments up to 300°C (300°F).

Thus, the aircraft industry is increasingly utilizing thermoplastic CFRP to reduce weight and improve efficiency.

In addition, since CFRP is difficult to burn and requires a large amount of energy for incineration, the development and utilization of recycled carbon fiber is currently attracting attention.

CFRP sandwich panels will continue to evolve further as a core material for next-generation space equipment.

Summary

CFRP sandwich panels are used in a wide range of fields, including the aerospace and automotive industries, wind power generation, and sporting goods, due to their light weight and high rigidity.

For example, when used in aircraft airframe structures and automobile body parts, it can significantly improve performance by reducing weight and increasing fuel efficiency.

In recent years, the development of thermoplastic CFRP and recycling technology has led to improved heat resistance and more efficient manufacturing processes, and further expansion of its use is expected in the future.

If you are considering fabricating parts using CFRP sandwich panels, please contact us.Taiga."Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742