Cutting is also an option when considering PEI machining for component or product fabrication purposes.

This article describes the application scenarios of PEI and the merits of cutting PEI, along with its characteristics, merits and demerits, for those who want to know what kind of product manufacturing materials PEI is suitable for, and what merits and cautions should be considered in PEI cutting.

Please also refer to the following section for tips on how to select a contractor for PEI cutting work.

For more information about Taiga, click here.Table of Contents

What is PEI (polyetherimide)?

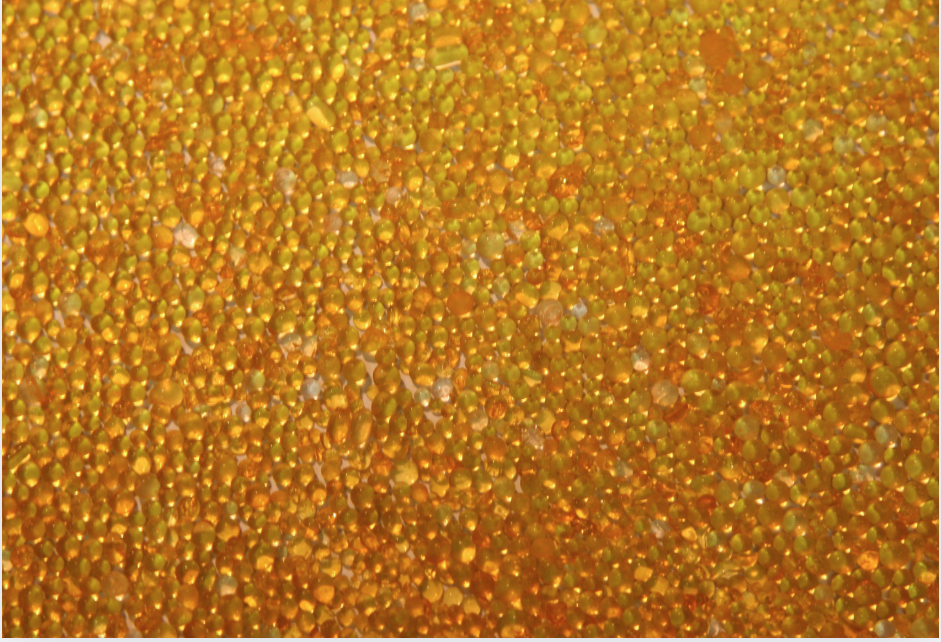

PEI is an amorphous plastic material that has both imide and ether bonds.

It is one of the super engineering plastics with a unique amber texture and even higher performance than engineering plastics.

Although it is rarely used in daily necessities, it is utilized in industrial products and medical equipment, taking advantage of its excellent properties.

Advantages of PEI

PEI offers the following advantages

- Heat resistant to 170°C for continuous use

- High chemical resistance

- High mechanical strength

- High electrical insulation

- High infrared transmission and high refractive index

- Flame retardant.

- High dimensional stability

- High formability

One notable advantage of PEI is that it can be used under high temperatures, with a glass transition temperature of 217°C and a continuous use temperature of 170°C.

It is also used in aerospace and aircraft components used in harsh environments due to its chemical resistance, high mechanical strength, electrical insulation, and flame resistance.

Disadvantages of PEI

The disadvantages of PEI are as follows

- Contains PA (Bisphenol A)

- Shock sensitive and notch sensitive

- Difficulty in chemical resistance and abrasion resistance

- High cost

PEI is restricted in its application to infant-related products because it contains PA.

It is also vulnerable to impact, especially at the corners, where it is easily scratched.

As is true of all amorphous plastics, including PEI, chemical resistance and abrasion resistance are also low.

As a material, it is very expensive, so processing costs should also be taken into consideration.

Typical types of PEI materials

Below is a summary of the main types of PEI.

- Standard grade: PEI with excellent mechanical strength and heat resistance that can be used in temperature environments of 150°C or higher

- Reinforced grade: PEI with glass fiber 30% blend, reinforced with glass fiber for higher stiffness and creep strength

- High strength grade: PEI composite based on polyetherimide (Ultem resin) reinforced with 50 vol% glass fiber weave

Since each grade has different characteristics, it is important to select the right material for the product you wish to manufacture.

Examples of situations and products where PEI is used

PEI is utilized in the following scenes and products, taking advantage of its characteristics.

| field of application | Examples of scenes and products |

| Telecommunications | Insulators used in optical fiber connectors optical transceiver modules optical components radio frequency connectors for optical communications base station cavity filter plastic cavity filter adjustment screw antenna internal fixing screw ring phase shifter bracket millimeter wave radome internal use (foamed PEI) |

| Aerospace Equipment | Avalve fuel valve inflight meal tray handle inflight interior seat frame storage shelf |

| Automotive | High temperature dielectric film (PEI film) for control valve oil pump light rider fender condenser |

| Medical Field | VentilatorAnesthesia machineSterile traySurgical guide pipetteAnimal laboratory cage |

| daily necessities | AppliancesMicrowave traysOptical frames |

Advantages of employing cutting in PEI processing

This section explains the advantages of choosing cutting for manufacturing parts and products using PEI.

Low-cost processing

Cutting can be performed with 3D-CAD data and programs.

Since molds are not required as in casting and injection molding, the cost of mold fabrication can be reduced.

For prototypes and small production runs, speedy processing can be achieved while keeping costs down.

PEI itself is expensive as a material, so it is also suitable when you want to keep production costs as low as possible.

High-precision finish can be achieved.

PEI cutting is performed by machine based on data and programs.

Therefore, it is less likely to be affected by the level of the technicians and will be able to achieve highly accurate processing.

Depending on the equipment used, adjustments can be made at the micron level.

In particular, PEI is widely used as a material for parts and products that require dimensional accuracy, such as in the aircraft, automobile, and space fields.

With cutting, PEI products that require precision in dimensions, surfaces, etc., will be able to achieve a satisfactory finish.

High degree of freedom of shape

Cutting is not limited by the thickness of the material as long as the machine can handle it.

In addition, since machining proceeds according to data and programs, machining of complex shapes is also feasible.

Cutting is also suitable for PEI production of parts with detailed and complex shapes, such as communication-related parts.

Cautions for cutting PEI

PEI has high notch sensitivity and is particularly vulnerable to stress concentration when cutting corners.

Be sure to provide sufficient R at corners to distribute stress, as chipping and cracking are more likely to occur.

If it is difficult to take a corner R, it is necessary to devise ways to reduce the amount of infeed and feed speed.

Also, burrs tend to occur during cutting, and care must be taken when making small holes or grooves due to the hardness of the material.

How to choose a contractor for PEI cutting

When considering PEI cutting, the finished product may depend on the contractor you hire.

The following is a step-by-step guide to selecting a contractor for PEI cutting.

Does PEI have extensive cutting experience and production examples?

Cutting of PEI requires attention to cracking, chipping, and burr formation.

Furthermore, because PEI itself is an extremely hard material, appropriate tools must be selected for use in the cutting process.

Therefore, choose a supplier that has extensive experience in manufacturing products and examples of PEI cutting. A contractor with an extensive track record is likely to have a high level of technical expertise.

In particular, when considering PEI product manufacturing, which requires high dimensional accuracy, please check PEI cutting results and case studies before making a request.

Is the company capable of cutting other super engineering plastic materials?

A supplier that handles cutting of super engineering plastics other than PEI will have extensive knowledge of PEI and other super engineering plastic materials.

Cutting with materials other than PEI can also be considered, which will expand the range of product manufacturing.

Materials that can be handled in cutting processes are often introduced on the official websites of vendors, so please check in advance.

Processing costs and delivery time

Cutting is also an option when considering PEI product fabrication without cost or delivery time, as it can be produced without the need for tooling.

However, the actual processing cost and delivery time will vary depending on the vendor you request.

Once you have found a potential client, be sure to confirm the actual costs and turnaround time by confirming delivery dates and requesting quotes.

Summary

Along with an overview of PEI as a material and its merits and demerits, we have explained the merits and demerits of PEI cutting and the precautions to be taken during processing.

PEI is a material used in precision equipment and components in various fields, including aerospace.

While PEI cutting has many advantages, there are also disadvantages and cautions, so be sure to request the services of a contractor with high technical capabilities and a wealth of experience.

If you are considering manufacturing components using PEI, please contact us!Taiga."Please make use of the following

Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742