Inconel, an alloy material, is hard and difficult to cut.

Therefore, in recent years, 3D printing has been attracting attention as a processing method for Inconel.

That being said, I'm still asking, "What kind of products can Inconel be used for?" "Are there any precautions to take when 3D printing Inconel?" Many people may have questions such as "What kind of products can Inconel be used for?

In this article, we will discuss the characteristics and uses of Inconel, as well as the benefits and cautions of 3D printing Inconel.

For more information about Taiga, click here.Table of Contents

Inconel 718 features used in 3D printing

There are many different types of Inconel, a synthetic metal with high stiffness and corrosion resistance at high temperatures.

In particular, Inconel 718, a difficult-to-machine material, can be efficiently modeled by utilizing 3D printing.

The following is a step-by-step description of the features of the Inconel 718, which is an option when considering 3D printing.

Difference between Inconel 718 and regular Inconel

The differences between Inconel 718 and other Inconels are as follows

| type | feature |

| Inconel 718 | Precipitation-strengthened; retains strength and corrosion resistance under temperatures from -250°C to 700°C; good weldability; difficult to cut and machine |

| Inconel 600 | Solid solution strengthened, high durability at high temperatures, oxidation resistance, and corrosion resistance |

| Inconel 601 | Solid solution strengthened, improved oxidation resistance and carburization resistance |

| Inconel 625 | Solid solution strengthened, high strength and toughness even at low temperatures, high corrosion resistance and high temperature strength |

| Inconel X-750 | Deposition strengthened type・High durability and fatigue resistance at high temperatures |

| Inconel 825 | ・High corrosion and corrosion resistance |

Examples of major Inconel applications and products

Inconel 718 is a synthetic metal containing large amounts of molybdenum and niobium and small amounts of aluminum and titanium.

Because of its ability to maintain mechanical strength at low to high temperatures, it is utilized in the following applications and products.

- Aerospace development (gas turbines, engine jet nozzles, rocket tanks, etc.)

- nuclear industry

- thermal power station (i.e. using combustion)

- Various plants

- Refuse incinerator

- Components for instrumentation, power and equipment industries (casings, high-voltage bolts, springs, etc.)

Advantages of Using Inconel in 3D Printing

In addition to traditional methods, metal 3D printing is another way to process Inconel.

This section describes the advantages of using 3D printing for Inconel processing.

Inconel, a difficult-to-machine material, is a good match for 3D printing.

Inconel is a difficult material to cut because of its property of retaining strength at high temperatures, poor thermal conductivity during machining, and easy tool wear.

In this respect, 3D printing allows for the efficient molding of Inconel, a difficult-to-machine material, because it is created by layering materials.

Capable of molding a wide range of shapes

Because 3D printing involves layering materials, it is possible to create complex shapes that are not possible with metal fabrication methods such as cutting or casting.

Since modeling proceeds based on CAD data, highly accurate modeling using Inconel can be realized.

Reduced number of parts and more efficient modeling

Another advantage of 3D printing is that parts can be modeled without joining or gluing them together.

Since the lamination process follows the shape of the design data, there is no need to laminate parts one at a time.

In addition to completing the modeling work in a single step, the elimination of adhesion and other processing also improves overall production efficiency.

Even parts made of Inconel, a difficult-to-machine material, can be fabricated efficiently.

Suitable for small lots and prototype modeling

3D printing can begin as soon as materials and CAD data are available.

As with casting and forging, there is no need to fabricate molds, and molding can be done at a lower cost and in a shorter period of time.

When you want to change the specifications of a prototype, there is no need to rebuild the mold; you only need to modify the CAD data.

Small-lot production and prototyping of products using expensive Inconel can also be achieved at a reduced cost by using 3D printing.

Cautions for Inconel 3D printing

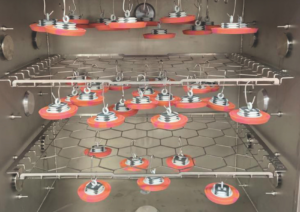

Inconel products after 3D printing require separate heat treatment due to their low hardness.

Some companies that support 3D printing may not be able to handle heat treatment, so be sure to check with them at the time of request.

In addition, since Inconel itself is an expensive material, be sure to select a vendor with the skills and know-how to achieve the ideal modeling so that there is no waste of material.

How to 3D Print Inconel

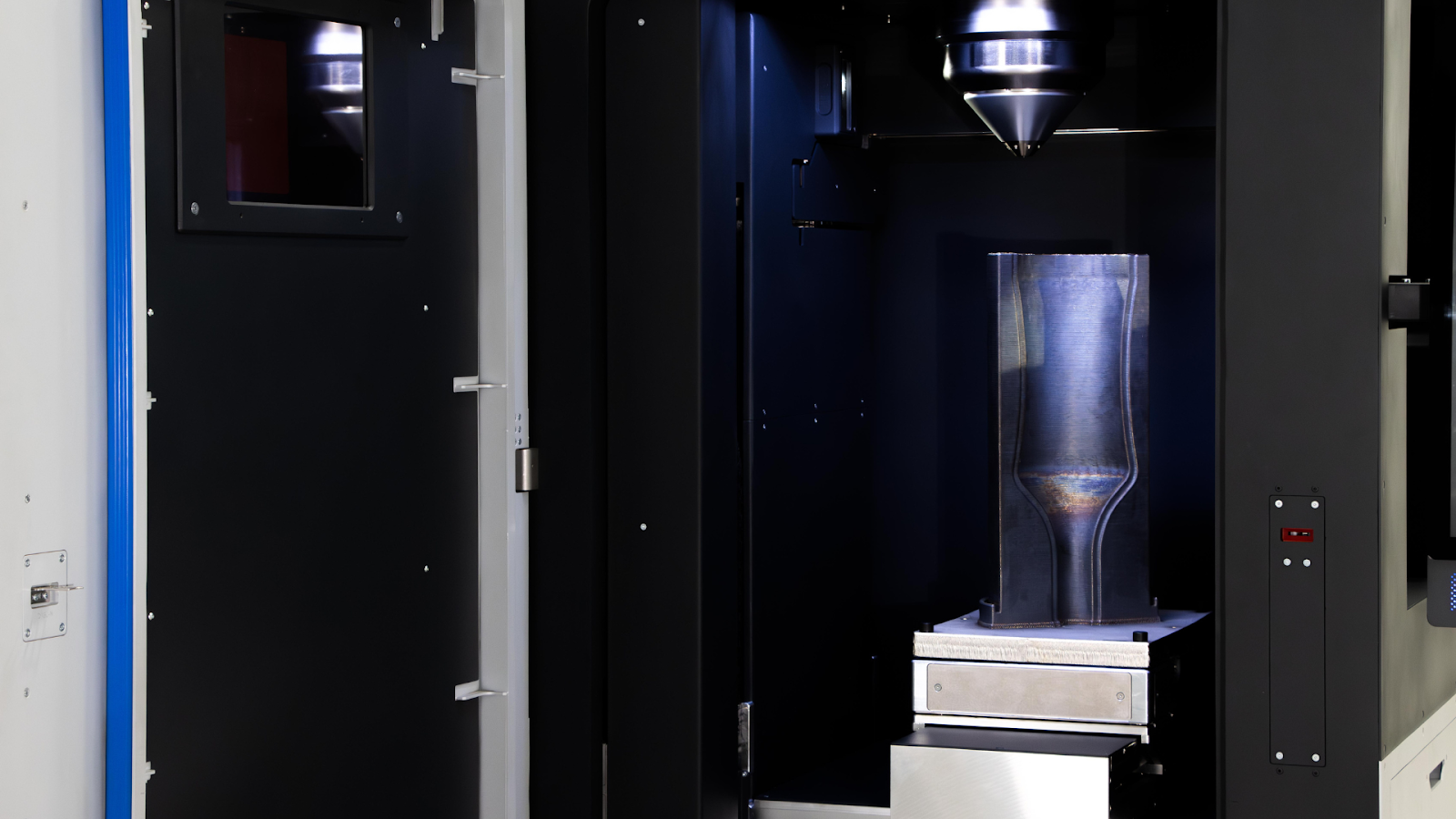

Inconel's main 3D printing method is the wire DED method.

The wire DED method is a method of modeling in which metal wires are melted by a heat source and layered one layer at a time. The Meltio M600, a representative wire DED system, uses the DED method with a laser, enabling high-precision, high-density modeling.

Compared to other methods, it has a high molding speed and excellent material utilization efficiency, making it suitable for fabrication and repair of large parts. In addition, because it does not use powder materials, it has the advantage of low dust generation and high safety.

The wire DED method is suitable for manufacturing high-strength and high heat-resistant Inconel parts, and is used in the aerospace and energy industries.

How to choose a vendor for 3D printing in Inconel

In order to achieve 3D printing of Inconel, it is necessary to request the services of a highly skilled and reliable vendor.

The following is a step-by-step guide on how to choose a vendor, which you should keep in mind even if you are considering 3D printing for Inconel for the first time.

Does it support Inconel 3D printing?

First, be sure to choose a vendor with Inconel's 3D printing experience.

With a proven track record, it is likely that the vendor will be able to understand the characteristics of Inconel while achieving appropriate 3D printing modeling.

Inconel is an expensive material, so be sure to choose a highly skilled contractor to avoid material waste.

Is it compatible with metal materials other than Inconel?

Different metal 3D printing companies support different metal materials.

Make sure it is compatible with Inconel as well as other metal materials.

Depending on what you are considering modeling, materials other than Inconel may be the best choice.

A contractor who works with metal materials other than Inconel will be able to offer flexible suggestions.

What are the molding costs and turnaround time?

Even with the same material, the cost and turnaround time for 3D printing varies from vendor to vendor.

Once you have identified a potential client, be sure to confirm specific costs and delivery dates.

It is especially important to check the cost of Inconel, as it is an expensive material.

Are there options for secondary processing, etc.?

Depending on the part or product to be modeled with Inconel, post-processing may be required.

For example, heat treatment is performed to produce hardness and to remove surface roughness.

If a 3D printing company also handles secondary processing after modeling, you can efficiently proceed with production by making a collective request.

Summary

Along with the features and benefits of Inconel, the advantages and cautions of 3D printing for Inconel were explained.

Because Inconel retains its hardness and corrosion resistance in low to high temperature environments, it is a material in high demand for components and equipment used in harsh environments.

However, since the materials themselves are expensive and difficult to cut, appropriate processing methods, including 3D printing, must be selected.

When 3D printing, choose a vendor that has expertise in handling Inconel materials to produce a satisfactory product.

If you are considering manufacturing parts using Inconel's 3D printingTaiga."Please make use of the following

Taiga is a service that allows you to consult with experienced suppliers free of charge. It is possible to develop difficult or new parts, produce small quantities, and proceed from prototyping to mass production in a cost-effective and efficient manner.

0120-987-742

0120-987-742