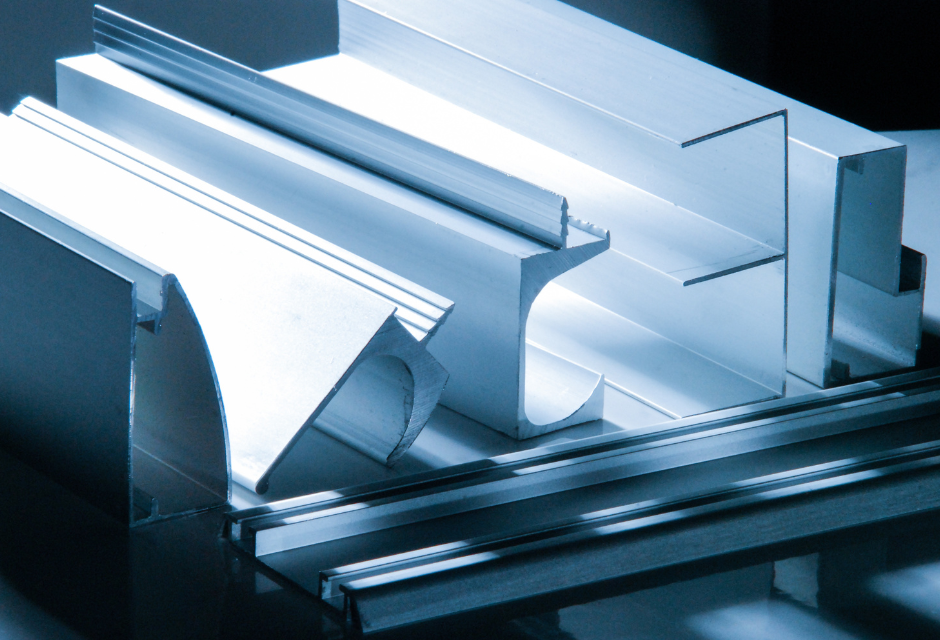

With its many properties, aluminum has become an indispensable material in modern industry.

Although the material is used in familiar items, few people understand its specific characteristics.

This article will therefore provide a detailed description of the characteristics, types, and precautions of aluminum.

For more information about Taiga, click here.Table of Contents

What is aluminum?

Aluminum is the most common nonferrous metal.

It is used in a wide range of applications because it has many characteristics different from ferrous metals.

Aluminum is such a relatively young metal, having been discovered only about 200 years ago.

The reason why it was not discovered until recently is that aluminum was a material that existed in minerals and soils as various compounds.

This made it difficult to find as a natural metal, and until recently it has not seen the light of day.

Aluminum was discovered by the English electrochemist "Humphry Davy".

Later, the successful extraction of metallic aluminum from aluminum chloride led to its use in industry.

Characteristics of Aluminum

Let us now take a closer look at the characteristics of aluminum.

light (i.e. not heavy)

Aluminum is very lightweight compared to other materials.

Weighing only about one-third as much as steel, its lightweight properties are used in a variety of fields, including transportation equipment, construction materials, and mobile home appliances.

Rust-resistant

Rust resistance is another characteristic of aluminum.

Aluminum is now used in a variety of products as the second most common metal after steel because of its superior corrosion resistance.

This is because aluminum oxidizes even in the atmosphere at room temperature, forming an oxide film about 0.2 microns thick on the surface.

This makes the material very rust-resistant and easy to use.

High strength

Aluminum itself is not that strong, but when alloyed with other metals, it becomes even stronger.

In particular, duralumin aluminum, to which zinc and magnesium are added, has high strength and is used as a material for aircraft and large structures.

Easy to process

Another feature of aluminum is that it is easy to process.

Aluminum is also suitable for plastic working and for casting.

It is also easy to cut and weld.

Because of this ability to incorporate a variety of processing methods, it is used in a wide range of products, including daily necessities.

High thermal conductivity

Aluminum is a metal that conducts heat easily.

Metals that conduct heat easily include copper, but copper is more expensive than aluminum and therefore less cosmetically pleasing.

On the other hand, aluminum is used in various products such as heat exchangers and heat sinks because it conducts heat easily and yet has high thermal conductivity.

High electrical conductivity

Aluminum is a good conductor of electricity as well as heat.

Copper, introduced earlier, is another metal with high electrical conductivity, but aluminum has nearly three times the conductivity of copper.

Furthermore, its low cost makes it an extremely easy-to-use material.

Incidentally, aluminum is sometimes used for power transmission lines, in which case strong aluminum alloys are often used.

Easy to play

In recent years, there has been a growing demand for environmentally friendly manufacturing.

Aluminum does not deteriorate easily even after prolonged use, yet its low melting point makes it easy to melt and reuse products.

The energy required for reuse is only 3% of that required to make a new product, and yet it maintains the same quality as a new product, making it an excellent material not only for the environment but also for the cost.

No magnetism

Aluminum is not affected by magnetic fields because it is a non-magnetic material.

As such, it is often used in parabolic antennas, ship magnetic compasses, and electronic medical devices.

In recent years, as technology continues to evolve, it is also beginning to be used in linear motor cars and other vehicles.

Highly reflective

High reflectivity is another characteristic of aluminum.

Aluminum has the ability to reflect as well as conduct heat and light.

Reflectance is further increased by increasing the purity or by applying a mirror finish.

These properties are utilized today in heating reflectors and space suits.

No toxicity

No matter how convenient a metal is, if it is toxic, it will be difficult to process.

However, aluminum is also found in soil, crops, seawater, and air, and is not toxic.

Aluminum is not edible, but even if a human were to ingest it, about 99% of it would be expelled, making it harmless.

There have been no health hazards in the past, and it is safe to use for products and materials that are easily touched.

High design quality

Aluminum is a beautiful material even in its raw state.

Anodizing, for example, gives it an even more beautiful appearance.

It is also possible to add color by electrolytic coloring, etc.

This design quality has led to its modern use in architectural exteriors and packaging materials.

Typical types of aluminum

Aluminum is a metal with a variety of properties, but in its pure form it does not bring out its true strength.

Therefore, iron, magnesium, and copper are basically added depending on the application.

Below is a detailed look at the typical types of aluminum.

1000 series

1000 series aluminum is more than 99.90% pure.

Because of its very high purity, it has excellent thermal conductivity, workability, and corrosion resistance as described earlier.

As such, it has outstanding ease of processing, but low strength.

Nevertheless, it is used to cover and decorate products and equipment because it contains as few impurities as possible.

2000 series

The aluminum of the 2000 series is stronger than that of the 1000 series.

An alloy called duralumin is typical of the 2000 series.

The addition of copper slightly reduces corrosion resistance but increases strength.

As such, it is often used in aircraft and automotive parts.

5000 series

5000 series aluminum is made by adding magnesium to enhance strength and corrosion resistance.

Its characteristics vary depending on the amount of magnesium, making it suitable for a wide range of applications, from decorative to structural.

The wide variety of alloys compared to other types is another characteristic of the Series 5000.

6000 series

Series 6000 aluminum refers to aluminum to which magnesium and silicon have been added to increase strength, corrosion resistance, and workability.

Among these, it is often used as a structural material because of its superiority in extrusion processing.

7000 series

7000 series aluminum is an alloy of zinc and magnesium.

Heat treatment makes this alloy the strongest of all aluminum alloys.

The representative of the 7000 series is called superduralumin, which is very expensive but has high strength and workability, and is often used as a material for aircraft.

Aluminum Cautions

The following are some of the caveats for such aluminum

Slightly lower strength than steel materials

・Corrosion may occur

Difficult to weld

Let's take a closer look at each of these.

Slightly lower strength than steel materials

Aluminum is a strong metal, and with additional processing it becomes an even stronger material.

However, it is less strong than steel materials.

This makes it suitable for soft and flexible structures such as airplane wings, but not for parts that require strength, such as gears.

Corrosion may occur.

Although aluminum itself is corrosion resistant, it can be corroded by salty environments or contact with other metals.

When using it as a product or component, it is important to carefully consider its compatibility with the environment and other metals.

Anodizing can also be used to reduce the risk from corrosion.

Difficult to weld

Aluminum forms an oxide film on its surface, and because its melting point is quite high at about 2,000°C, the oxide film must be removed when welding.

Also, as explained earlier, aluminum has high thermal conductivity and a low melting point, so heat is easily transferred when welding, and in some cases can cause dislocation.

To avoid such problems, it is important to gradually change the speed of the welding torch.

However, while changing the speed of the welding torch is easy to say, it can be quite difficult to put into practice.

If you want to improve the quality and productivity of your products, we recommend that you consult with a contractor with a proven track record.

For parts manufacturing, "Taiga" is recommended!

Aluminum, with its excellent workability, is used in a wide variety of products.

However, as just mentioned, aluminum is relatively difficult to process and requires advanced knowledge and skills, especially in welding.

For this reason, it is important to consult with a contractor with a proven track record in cases where in-house processing is difficult.

However, it is not so easy to find a reliable outsourcing partner or partner that fits your company's needs.

To solve these issues in the manufacturing industry, we have developed a service called Taiga.

Taiga is a platform designed to connect users and partners to provide a smooth and safe manufacturing experience.

A variety of convenient functions, such as chat, drawing editing, and re-purchase functions, allow you to proceed smoothly with material processing and manufacturing. If you are looking to improve productivity, efficiency, and safety in manufacturing, please feel free to contact us.

Summary

Aluminum is an easy-to-process metal with many characteristics. As such, it is used in many of our everyday objects.

Since aluminum in its raw state does not bring out its strength, iron, magnesium, copper, and other substances are often added according to the intended use. It can be said to be an extremely convenient metal because its characteristics change depending on the type and amount of substances added.

Such aluminum is particularly difficult to weld, and if you want to ensure quality and safety, it is recommended that you consult a contractor with a proven track record.

Taiga makes it easy for you to find a strong and reliable partner for aluminum processing.

It also reduces man-hours required for communication and progress management.

For more information about Taiga, click here.

0120-987-742

0120-987-742