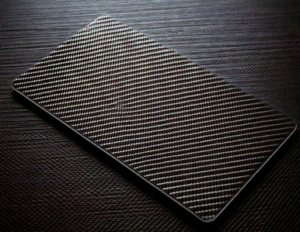

CFRP, which combines the lightweight properties of resin with the durability of carbon fiber, is a material used for a variety of applications and purposes, including weight reduction of equipment.

We are considering cutting CFRP for manufacturing CFRP parts and products, but we have been asking ourselves "Is it difficult to cut CFRP?" and "Is there a vendor I can request?" Is there a vendor I can request?" Many people may have questions such as "Is it difficult to cut CFRP?

In this article, in addition to the properties of CFRP and the differences from carbon graphite, a similar material, we will explain the difficulties of cutting CFRP and the precautions to be taken during the cutting process.

We also introduce how to select a vendor who can be commissioned to perform CFRP cutting work.

For more information about Taiga, click here.Table of Contents

What is CFRP (Carbon Fiber Reinforced Plastic)?

CFRP is a material made of resin reinforced with carbon fiber.

It is lightweight, at one-fifth the weight of steel and one-half the weight of aluminum, yet has high strength comparable to metals.

The material also has a good balance of other properties, such as corrosion resistance and shock absorption.

What is carbon graphite similar to CFRP?

Carbon braphite is a material formed exclusively from carbon (carbon), such as graphite, graphite, black lead, and graphite ink.

Because it is made by firing carbon, it is included in a type of ceramic material.

Another material similar to CFRP is CC composite, which is graphite graphite reinforced with carbon fiber.

CC composites are lightweight like CFRP, but resin is not included in their composition.

Three reasons why cutting CFRP is difficult

CFRP may be required to be machined by cutting depending on the application.

However, CFRP is one of the difficult-to-machine materials that are difficult to cut.

This section explains, in turn, the main reasons why cutting CFRP is difficult.

High strength, fiber layers easily detach

CFRP boasts high strength comparable to metal through the use of carbon fiber.

Therefore, the disadvantage is that the fiber layer of carbon fiber tends to peel off when the tool is applied during cutting, which prevents efficient machining.

Cutting CFRP is also difficult in that machining is time-consuming.

Easy tool wear

Because CFRP is a hard material, it has the disadvantage of being easily worn by tools used in cutting processes.

In general, cutting oils are used in metal cutting processes to prevent tool wear and improve machining efficiency. However, cutting fluid cannot be used for CFRP due to the characteristics of the material.

In addition to this, cutting CFRP is also difficult in that the machining process must be carried out while selecting tools that allow the cutting process to proceed properly and changing tools as needed.

Dust produced by processing is bad for the human body.

When cutting CFRP, dust is generated from the cut area.

Measures must be taken to prevent dust from getting on the skin, which can cause itching, and inhaling it can be harmful to the human body.

The hurdle for cutting CFRP is also high in terms of creating a working environment that does not generate dust.

Points to note in cutting CFRP

Since CFRP is a difficult-to-machine material, various considerations must be taken into account in order to proceed with the cutting process.

The following is a step-by-step explanation of the points to keep in mind when cutting CFRP.

Cutting fluid cannot be used for cutting CFRP.

Because of its tendency to absorb oil, CFRP cannot use cutting oils used in metal and other cutting processes.

If used incorrectly, there is a risk that cutting oil that has been adsorbed onto the CFRP will remain without being removed.

In addition, high technical skills are required for efficient machining without cutting oil.

Requires processing that takes anisotropy into account

CFRP is an anisotropic material made of resin and carbon fiber, so when cutting, the fiber direction, loading configuration, and characteristics of the matrix material resin must be taken into account.

This is because processing resistance varies depending on the direction and amount of fibers and the lamination configuration, and thermal properties vary depending on the resin used.

Successful cutting of CFRP requires specialized knowledge and know-how that can take into account the anisotropy that is unique to CFRP.

What is required for CFRP cutting

While cutting CFRP is difficult, it is not impossible.

We will explain the key points that are necessary to achieve satisfactory CFRP cutting.

Selection of appropriate cutting tools

CFRP has the disadvantage of being a hard material, which makes cutting tools prone to wear.

Cutting with tools that are still worn will adversely affect the accuracy of the CFRP cutting process.

Therefore, selecting appropriate cutting tools, such as cemented carbide or diamond, will prevent tool wear, improve machining efficiency, and reduce costs.

Cutting speed adjustment

When cutting CFRP, it is important to select the appropriate cutting speed as well as tool selection.

If the cutting speed is too fast, heat from cutting tends to accumulate in the tool and accelerate tool wear.

Slow cutting speeds pose risks such as rough machined surfaces, chattering, and poor machining efficiency.

Adjusting to the appropriate cutting speed will lead to highly accurate and efficient CFRP cutting.

How to choose a contractor for CFRP cutting

In order to manufacture satisfactory parts and products by cutting CFRP, it is important to select the right supplier.

The following is a step-by-step explanation of points to keep in mind when selecting a supplier for CFRP cutting.

Does it support cutting of CFRP and carbon materials?

First, be sure to select a supplier that is capable of cutting CFRP and carbon materials.

Because CFRP is a difficult-to-machine material, appropriate tool selection, machining speed, and machining conditions must be set for cutting.

A vendor that handles cutting of CFRP and carbon materials will have the expertise and skills to proceed with the cutting process.

Do you have experience in processing the product you wish to request?

CFRP is a material used in a wide range of fields due to its various properties, including light weight and high hardness.

If you are considering cutting, check whether the company is capable of cutting the product you want to manufacture and whether it has experience in this area.

If the company already has the same or similar processing experience to the product you want to request, it is likely to be able to manufacture the product as desired.

Time to delivery and processing costs

Even when the same materials are processed under the same conditions, the delivery time and processing costs incurred will vary depending on the vendor requested.

Be sure to request a supplier that is not only capable of CFRP cutting, but also satisfactory in terms of delivery time and cost.

Failure to confirm delivery dates and costs can lead to problems such as late delivery and cost pressures.

Another key factor in selecting a vendor is to request quotes and compare delivery times and costs.

Summary

We explained the properties of CFRP, reasons why cutting CFRP is difficult, and points to keep in mind when cutting and selecting a vendor.

Although cutting CFRP enables high-precision product manufacturing, the cutting process itself is difficult and requires specialized knowledge, skills, and techniques.

When considering CFRP cutting, choose a supplier with reliable technology and responsiveness to handle your request.

If you are considering manufacturing parts utilizing CFRP processing, please contact us.Taiga."Please make use of the following

Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742