Invar, a synthetic metal with excellent dimensional stability, is widely used in applications requiring dimensional accuracy, such as control equipment.

When considering prototyping products using invar or fabricating special shapes, metal 3D printing is an option.

On the other hand, "Are there any vendors that support metal 3D printing in Invar?" "What kind of products can be made with Invar?" Some people may have questions such as "What kind of products can I make with Invar?

In this article, we will discuss the advantages and disadvantages of 3D printing invar along with its characteristics, advantages, and disadvantages as a metal.

For more information about Taiga, click here.Table of Contents

What is Invar and can it be built with a 3D printer?

Invar is a synthetic metal containing iron, nickel, manganese, cobalt, and carbon.

Due to the simultaneous thermal expansion when the temperature rises and the volume contraction that occurs when the material converts from ferromagnetic to paramagnetic, it boasts high dimensional stability with little dimensional change within a temperature range of -250 to 200°C.

Invar products have generally been made from rolled bar or plate or by casting, but recently 3D printing has also been attracting attention.

Although 3D printing of invar is not yet common, and the number of companies that support it is small in comparison to the total number of companies, development and research of invar materials based on 3D printing has been conducted in recent years.

Main types of invar

The characteristics of each type of invar are as follows

| type | feature |

| Invar 36. | High dimensional stability within standard invar constant temperature |

| super invar | Alloys with 4-5% cobalt added to Invar have an even lower coefficient of thermal expansion, 1/100th that of iron. |

| High Strength Invar | Invar with added titanium and other materials to increase strength |

| corrosion-resistant invar | Invar with added chromium, stainless steel, etc. to increase corrosion resistance |

Advantages of Invar Materials

Invar materials have the following advantages

- High dimensional stability at specific temperatures

- Relatively high corrosion resistance

- Strong magnetism below Curie point (276.7°C) due to ferromagnetic alloy

- Excellent metal properties

- Good cost performance

Invar's dimensions remain virtually unchanged within a temperature range of -250 to 200°C.

As a result, they are used in a variety of applications that require strict dimensional accuracy.

It also has relatively high corrosion resistance due to the presence of nickel.

It also retains the excellent properties of metals, such as electrical conductivity, weldability, and elasticity.

It is also cost-effective because it is available at a lower cost than other metals with low expansion properties.

Disadvantages of invar material

Invar materials also have the following disadvantages

- Dimensional stability is compromised outside of temperature

- Oxidation resistance decreases at high temperatures.

- Rust may occur in humid environments

- Insensitive to acids and alkalis

Invar materials can guarantee dimensional stability in a limited range, but deformation will occur outside of the temperature range.

It should also be noted that although the material can retain its dimensions at high temperatures, its oxidation resistance is reduced.

Besides, although corrosion resistance can be demonstrated in dry conditions, rust may occur in humid environments.

It is weak against acids and alkalis and does not have high chemical resistance.

Examples of major applications and products of Invar

Invar's ability to withstand temperature changes allows it to be used in the following applications and products.

- precision equipment

- Watch parts

- Surveying instruments (datum scales and datum lines)

- Optics (frames and lens holders)

- electronic equipment

- Semiconductor manufacturing equipment (stages and frames)

- LNG tanker (tank)

- Aerospace (aircraft, rocket and satellite components)

- Automobiles and transportation equipment (engine and brake parts)

- medical equipment

- Building Materials

Advantages of 3D printing invar

This section describes the benefits of 3D printing invar.

Difficult-to-machine invar materials work well with 3D printing

Invar is a difficult-to-machine material and is considered difficult to process by cutting.

And since invar is often used in precision equipment applications, its inability to be machined with high precision has been a bottleneck.

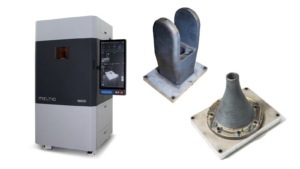

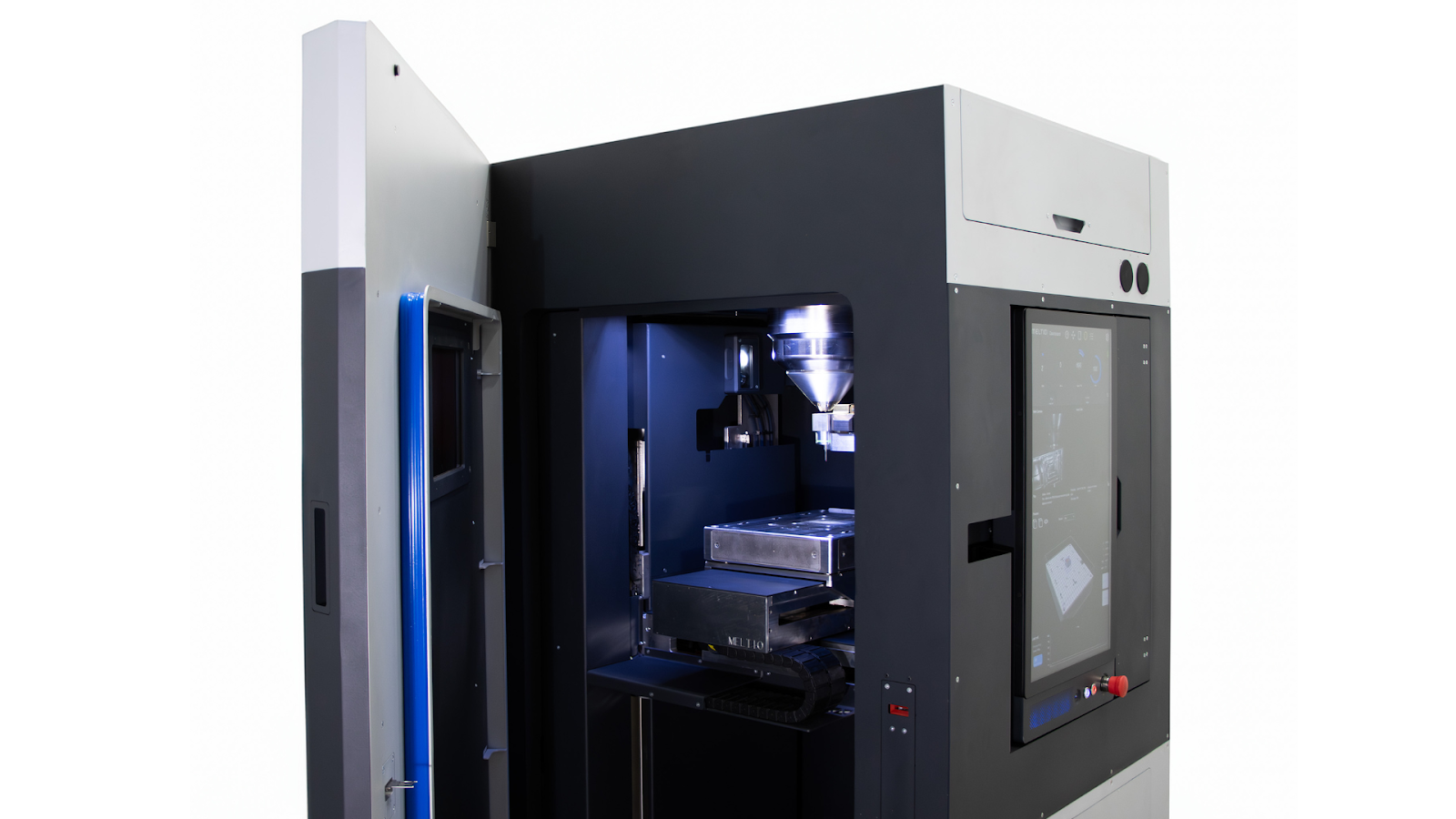

In recent years, however, with the development of metal 3D printers that can handle invar and the research and development of invar materials that are designed for 3D printing, processing by 3D printing is beginning to become more widespread.

With 3D printing, which uses layering, even difficult-to-machine materials such as Invar can be processed with a high degree of precision.

Can be formed into various shapes with a high degree of freedom of shape

Metal 3D printers perform modeling by layering materials based on data created by CAD software.

Because it is capable of faithful modeling to data, it is also suited for processing that requires complex shapes and high dimensional accuracy.

Efficient modeling due to fewer parts

Metal 3D printers can create free-form shapes according to CAD data.

Therefore, there is no need to go through the process of making parts one by one and gluing them together to make a finished product, as is the case with conventional processing methods.

The ability to produce finished products and prototypes in a single processing step will help streamline the manufacturing process.

Suitable for prototype modeling and small lot production

Metal 3D printing does not require molds, which are necessary for common metal fabrication methods.

This reduces the time and costs incurred in the fabrication of molds.

Prototypes and small-lot production using invar will be possible with 3D printing, with short delivery times and low costs.

Invar is not an inexpensive material, although it is a cost-effective synthetic metal with low expansion properties.

The advantages of 3D printing are also significant in terms of prototyping and small-lot production without wasting the cost of invar materials.

How to choose a vendor for 3D printing in Invar

Relatively few companies are capable of 3D printing invar, and you need to choose a reliable company to achieve satisfactory modeling.

This section explains how to choose a vendor for 3D printing of invar.

Does it support 3D printing of invar materials?

3D printing of invar materials is not yet common, and only a few companies support it.

To achieve component and product fabrication using Invar, choose a 3D printing company that supports Invar.

It is also a good idea to check the official website for processing results.

Can metal materials other than invar materials be considered?

Different vendors offer different types of components that can be 3D printed.

If a wide range of metal materials other than invar materials can be used, the range of products and components that can be processed will be expanded.

Another advantage is the variety of suggestions, as materials other than invar materials may be an option depending on the application and cost.

What are the costs and turnaround time for modeling?

The costs and turnaround time incurred in molding vary from vendor to vendor.

Be sure to select a vendor that can achieve the cost and delivery time you desire.

Is secondary processing possible?

In 3D printing, secondary processing such as surface treatment or polishing is required depending on the part or product to be modeled.

Different vendors will differ as to whether they support only 3D printing or post-processing and secondary processing as well.

If post-processing or secondary processing is available, it will only require one request, which will also lead to more efficient production.

Summary

Along with the features and benefits of invar, the advantages and cautions of 3D printing of invar were explained.

Invar is increasingly needed for parts and products that require dimensional accuracy, and 3D printing is expected to expand in the future.

Since there are still only a few companies that support 3D printing of invar, it is important to select and request a company with high technology and experience.

If you are considering manufacturing parts utilizing CFRP processing, please contact us.Taiga."Please make use of the following

Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742