- I want to know the principle of laser processing.

- I'm curious about the advantages and disadvantages.

Many people who are considering laser processing for their own product development may have this problem.

This article will explain the principles, types of processing machines, laser types, advantages, and disadvantages.

For more information about Taiga, click here.Table of Contents

What is laser processing? A Brief Explanation of Principles and Mechanisms

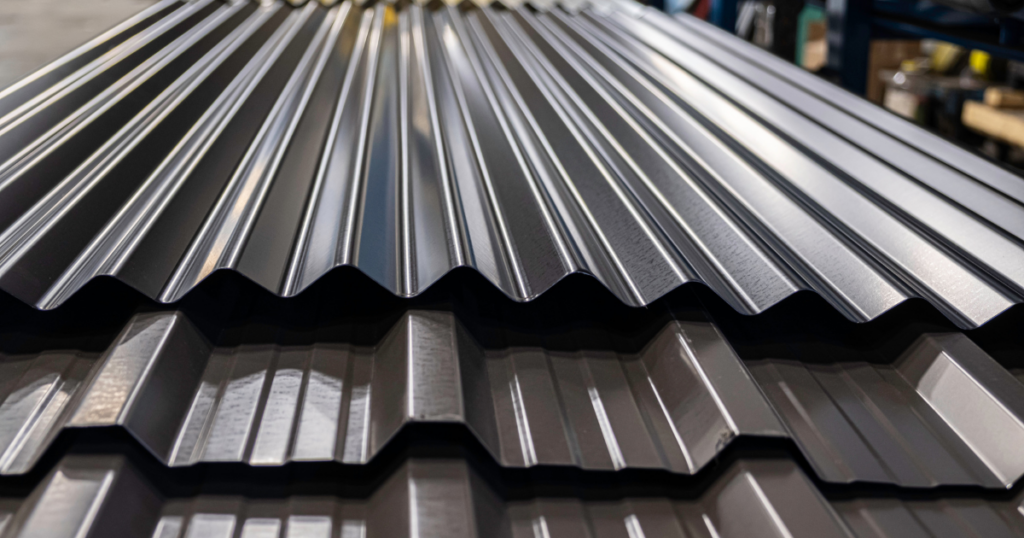

Laser processing is a processing method for drilling and cutting by irradiating a laser beam generated by a laser oscillator or other processing machine onto a material.

The principles of this process are directivity (directivity) and monochromaticity.

Because lasers are highly directional and monochromatic, they generate high-density energy when focused by a lens or other means.

Materials such as metals can be processed by converging lasers in a dedicated processing machine and irradiating high-density energy onto the material.

Types of lasers used in laser processing

There are various types of lasers used in laser processing, depending on the oscillator.

Different types of materials are suitable for different types of processing, so it is important to select the appropriate one.

The features of each type used in laser processing are summarized below.

| Types of Lasers | feature | Target materials and applications |

| solid-state laser | Can increase output while maintaining small volume | Steel, aluminum, copper, resin |

| gas laser | Uniform media and low loss | Transparent materials, wood, resin, leather, glass |

| liquid laser | Variable wavelength | Optical Fraction Measurement |

| semiconductor laser | Large output can be obtained with a small device. | Optical communication, laser printer, medical, CD, DVD |

The three devices that make up a laser processing machine

The following is a list of the main laser processing machines used for laser processing.

Laser oscillator system

A laser oscillator system is a device for oscillating light.

An excitation light source such as a lamp is irradiated onto a medium such as an individual or gas, and the light is repeated by mirrors in a resonator to emit light as a laser.

process optics

The processing engineering system is used to focus the laser generated by the laser oscillator and irradiate it to the table.

There are two main types: one that uses reflective mirrors and the other that uses optical fibers.

Processed material system

The process material system consists of the table on which the workpiece is fixed and the workpiece itself.

In laser processing, the following engineering and thermal properties affect the workmanship of the workpiece.

- Reflectance of workpiece

- Absorption rate

- transmittance

The processing material system is responsible for controlling the light collector system and Taevil and setting the appropriate speed, which is necessary when processing while moving the irradiation position.

There are two types of processed material systems

| system | feature |

| staged | The laser is fixed in place and the processing position is moved by the stage. |

| robotic | Automatic processing is possible with programmed movements, independent of operator level, and effective in stabilizing quality. |

Advantages of Laser Processing

This section explains the various advantages of laser processing.

High processing efficiency

Laser light has higher energy than other heat sources used in thermal processing and has the advantage of speedy processing due to its high heat input efficiency.

Compared to other processing methods, cutting, surface treatment, and other processing speeds are faster, leading to increased efficiency in overall processing operations.

No dies are required for cutting as in press cutting, eliminating the need for die replacement and management.

Complex processing and high flexibility in processing

In addition to using graphic data, laser processing enables fine and complex processing by adjusting irradiation position and power.

Specifically, the following processing is supported

| processing method | feature |

| Laser Removal | A process in which an object is melted by heat, blown away, or otherwise evaporated by high energy in a short period of time. It can cut materials, make holes, and engrave designs. |

| laser welding | A process for joining heated metals and resins by melting them. We support overlap welding, butt welding, and other welding methods. |

| Laser Modification | Processes include quenching, annealing, marking, and cladding, in which the surface of a material is heated and cooled rapidly to change its surface composition and improve its properties. |

| Laser deformation | Bending process using thermal stress of irradiated material. Requires advanced technology. |

Because the laser beam is narrow, the laser is also good at fine processing other than cutting.

For example, it is possible to drill holes in fine areas that are not possible with other processing methods, reproduce complex kanji characters and fine patterns, and process complex curves.

It is used not only for finishing, but also for applying a rust-resistant finish to the surface.

Various materials can be processed.

Laser processing can be performed without touching the object, so as long as the laser beam can be absorbed, processing is possible regardless of the hardness of the material.

For example, the following materials can be supported

- Hard materials (metal, stone, synthetic rubber, etc.)

- Soft materials (wood, resin, leather, fabrics, textiles, etc.)

- Thin materials (e.g., paper)

- Brittle materials (e.g., ceramic)

Good finish after processing

Laser processing does not produce protruding metal such as burrs or chips in the material after processing.

As a result, not only is the finish beautiful, but post-processing such as polishing to remove burrs and chips is also unnecessary.

Hassle-free maintenance of processing machines

In laser processing, there is no contact between the material and the tool during processing.

Therefore, there is no wear and tear on knives, tools, grinders, etc., as with other processing methods, and the advantage is that maintenance is less time-consuming.

No dust or chips will be generated when cutting materials, which will save time and effort in removal.

The only maintenance required is simple, such as cleaning mirrors and lenses, cleaning assist air, etc.

Disadvantages of laser processing

While laser processing has some advantages, it also has disadvantages.

Many materials cannot be processed.

In some cases, the following materials cannot be laser processed.

- Thick material

- Highly reflective material

- Materials that generate hazardous substances

This is because thicker materials tend to move away from the focal distance of the laser beam, reducing its power and making it impossible to process.

In addition, highly reflective materials such as copper and aluminum will repel laser light.

However, by selecting the appropriate laser processing machine, it may be possible to process even highly reflective materials.

Other materials that cannot be processed include polyvinyl chloride, which emits toxic gases when exposed to laser beams, and Teflon and fluorine, which emit toxic substances.

Slightly higher processing costs

In addition to the cost of the processing machine itself, the following costs are incurred for laser processing.

- electric utility expense

- gas money

- Consumables such as focal lenses and mirrors

In addition to being expensive, laser processing machines with high-performance laser oscillators and controllers incur many running costs.

Therefore, it is more cost-effective to hire a processing company than to install processing equipment in-house.

Processing takes time

Laser processing is a method of processing materials by pinpoint irradiation and melting them.

Compared to other processing methods such as pressing and cutting, machining takes longer.

Note that although increasing the power increases the cutting speed of the laser cutting machine, it also increases the tendency for burrs and dross to occur.

Summary

The outline and principle of laser processing, types of processing machines, and advantages and disadvantages of laser processing were explained.

Laser processing also enables processing with a high degree of precision and reproducibility that is not possible with other processing methods.

However, the cost tends to be higher, so it is important to choose the right vendor for high quality processing.

If you are considering manufacturing parts using laser processing, please contact us!Taiga."Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742