In recent years, 3D printing has been attracting attention for its ability to mold complex shapes with high precision.

Typical materials that are compatible with 3D printing are resins, but in fact, metals, including stainless steel, can also be 3D printed.

On the other hand, there are some people who ask, "What metals can be 3D printed?" "Are there any precautions for 3D printing stainless steel, for example?" Some of you may have questions such as "What are the most common metals that can be 3D printed?

In this article, we will explain the advantages of 3D printing stainless steel processing, along with the types of stainless steel used in 3D printing and their advantages and differences from regular stainless steel.

For more information about Taiga, click here.Table of Contents

Stainless steel used in 3D printing is "SUS316L

Stainless steel used in metal 3D printing is mainly "SUS316L.

SUS316L is a highly corrosion-resistant stainless steel that forms a very thin oxide film of chromium on the surface to prevent rust from forming and new colors from forming inside.

First, we will explain the advantages and disadvantages of SUS316L based on its unique characteristics.

Advantages of SUS316L

The advantages of SUS316L are as follows

- Excellent heat resistance and corrosion resistance due to low oxygen characteristics

- Stable in high temperature environments.

- Excellent crack resistance

SUS316L is a material often used in harsh environments such as marine and chemical industry manufacturing plants, where it is subjected to high temperatures and corrosion resistance.

Due to its superior resistance to cracking during welding, complex shapes can be realized by machining.

Disadvantages of SUS316L

The disadvantage of SUS316L is its low hardness.

Especially when compared to SUS316, which is the same stainless steel, it has inferior mechanical strength.

Difference between SUS316L and ordinary stainless steel

The following list compares SUS316L with SUS316, a common stainless steel.

| type | corrosion resistance | weldability | magnetism | availability |

| SUS316L | High in saline and oxidizer environments | High (however, SUS316 may be more suitable depending on the intended use) | Weak magnetism. | Somewhat difficult to obtain |

| SUS 316 | High, but falls off in environments with salt and oxidizers. | high | non-magnetic | easy to obtain |

Main applications and product examples of SUS316L

SUS316L is used in the following applications and products, taking advantage of its excellent corrosion resistance even in harsh environments.

- Watches and jewelry

- Automotive Industry Equipment

- Food and chemical plants

- Modeling in the aerospace industry area

- pot used for cooking

Advantages of 3D printing stainless steel

This section describes the advantages of processing SUS316L with a metal 3D printer.

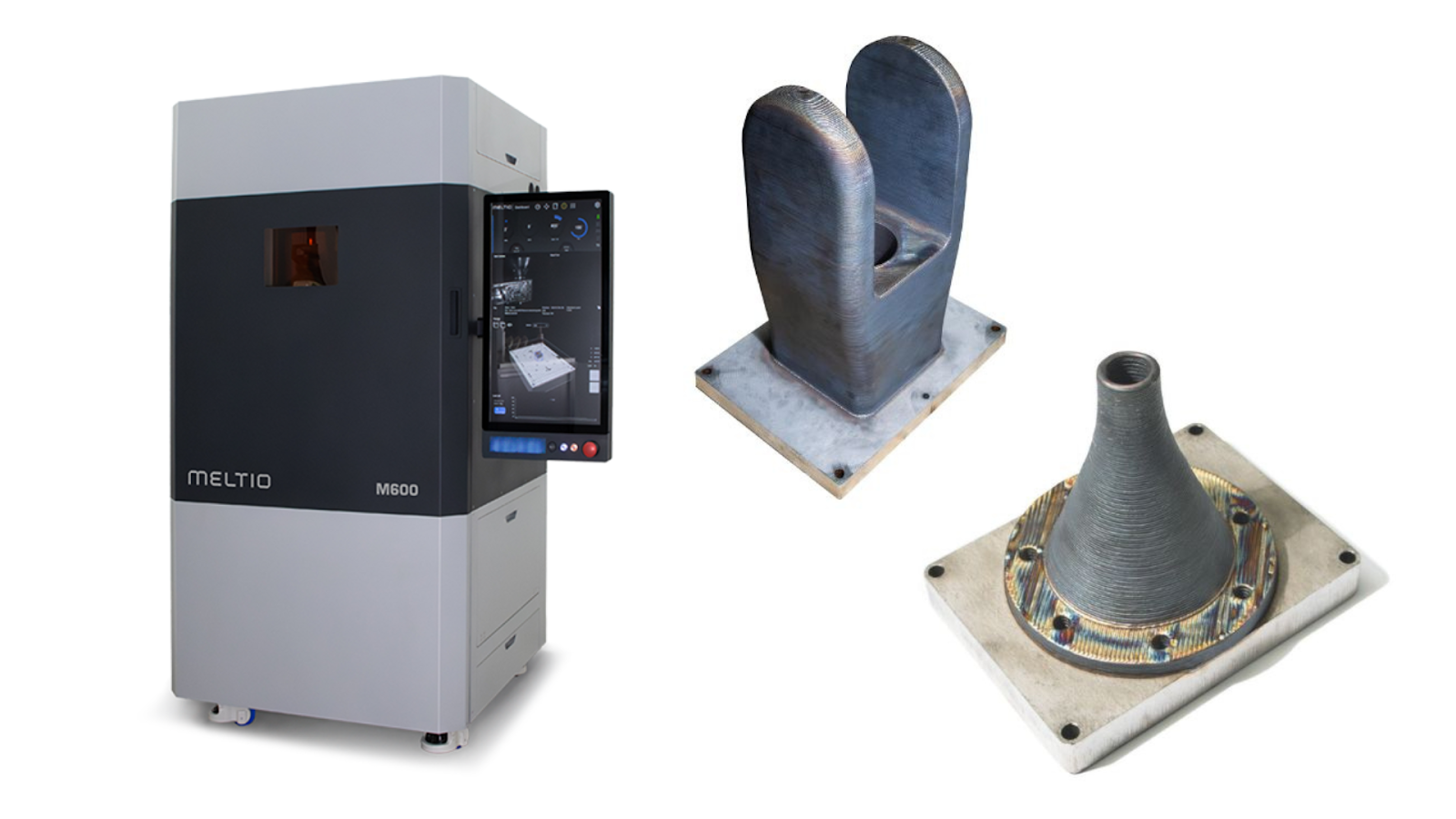

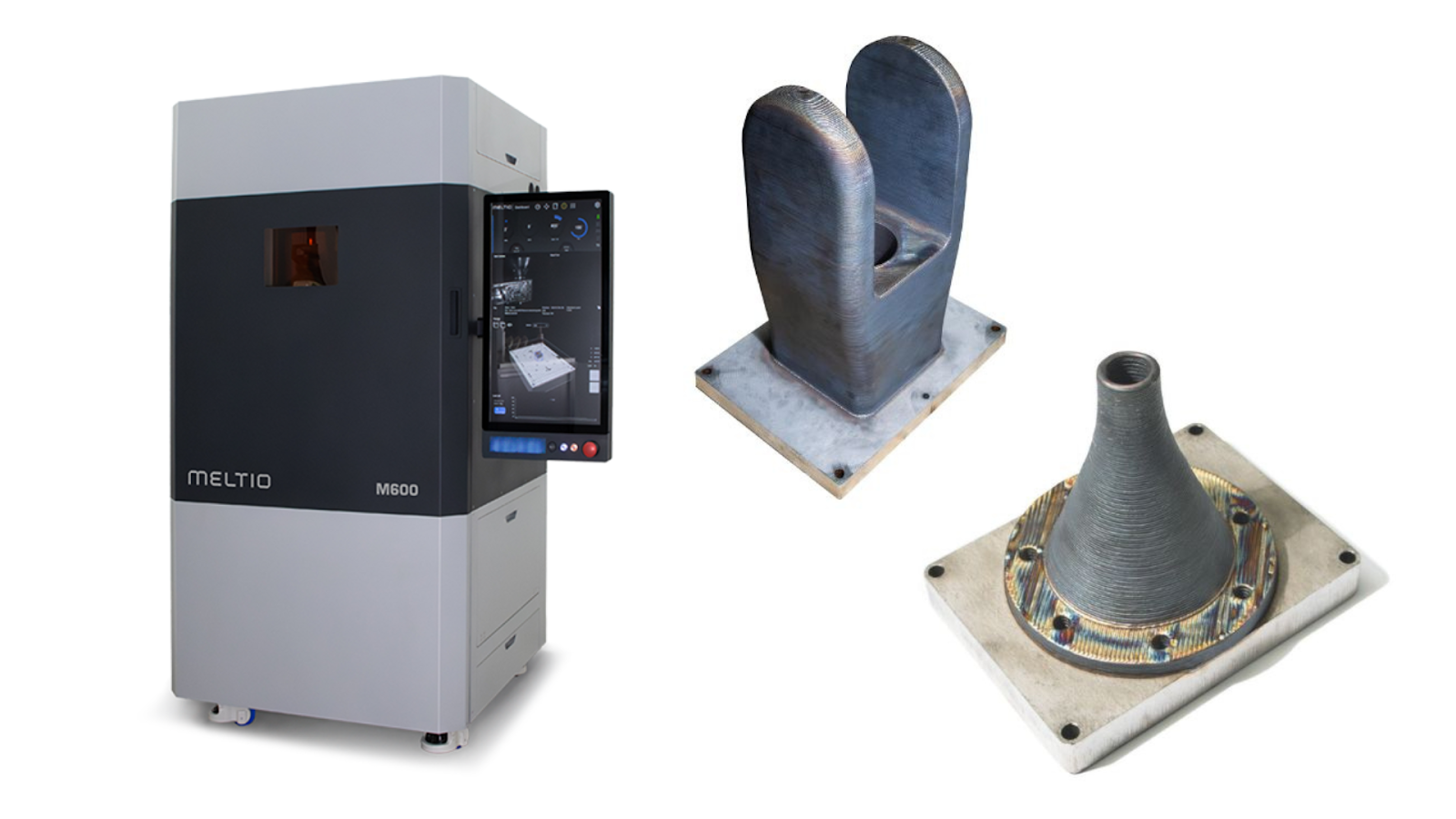

Capable of molding products with complex shapes

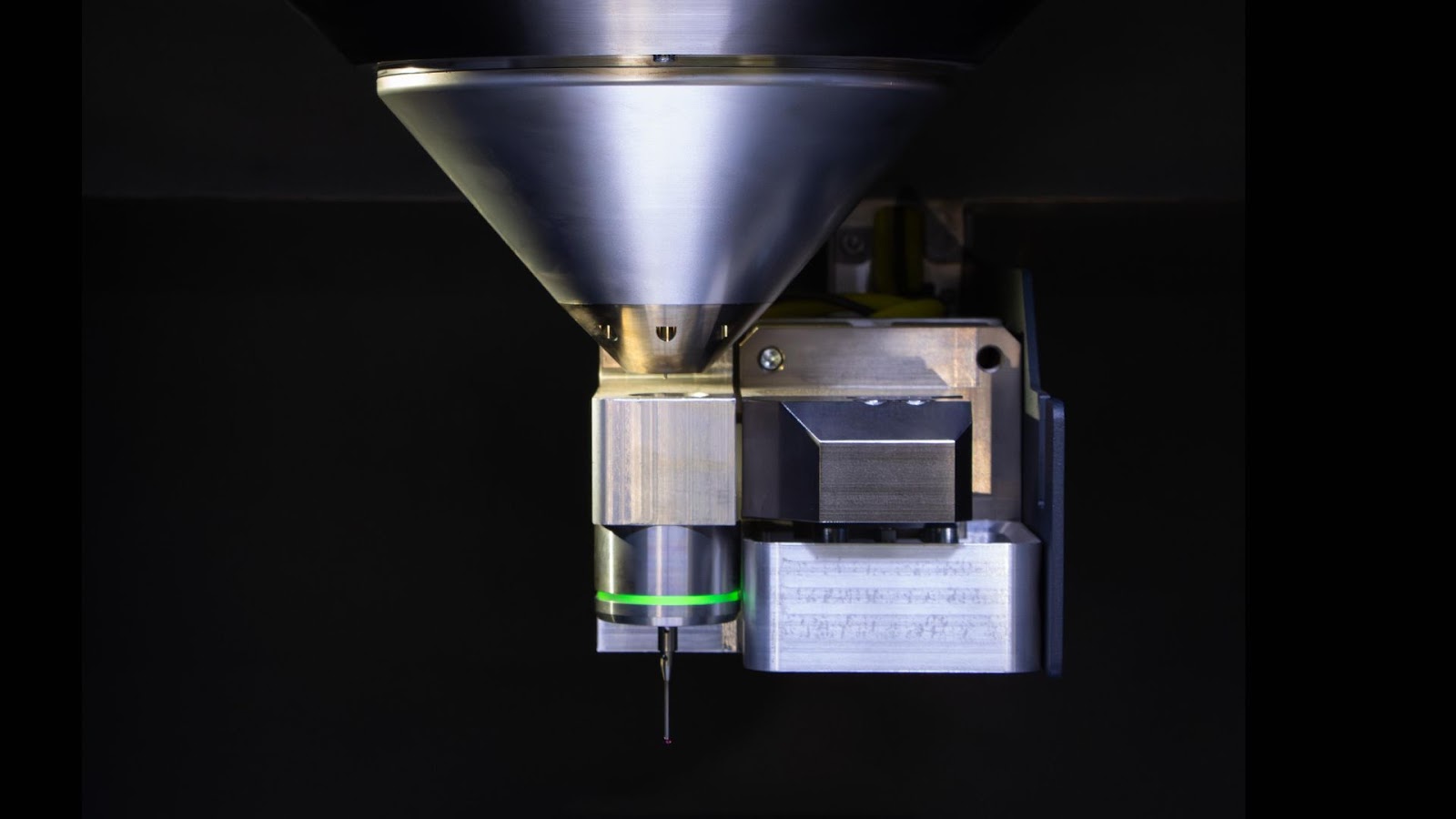

For example, in the case of a metal 3D printer using the wire DED method, the material is stacked and layered to advance the modeling process.

Therefore, products with complex shapes that cannot be formed by casting or cutting, which are common metal fabrication methods, can also be formed.

Whether you want to model stainless steel for industrial or marine equipment or components, 3D printing can produce the right shape for your application.

Reduced number of components

3D printing consumes only the materials used in product fabrication.

No non-reusable chips or swarf is generated as in the cutting process.

This is suitable for modeling while reducing costs because material loss can be minimized.

The ability to use SUS316L, which is more difficult to obtain than ordinary stainless steel, without loss is a major advantage.

Short-term delivery is possible

Resin-based 3D printing is often used to create prototypes, while metal 3D printing can be used to create final products.

In addition, since mold fabrication is not required, the time required for mold fabrication can be reduced and modeling can be done in a short period of time.

Can also mold small lots and prototypes.

With a metal 3D printer, as long as you have the materials and data, you can immediately start modeling your product.

In the case of processing methods that use dies, the dies themselves must be remade when specifications are changed, resulting in a large period of time and cost for small-lot or prototype production.

In this respect, 3D printers can be used in various development stages of SUS316L product manufacturing because they can model small lots and prototypes without hesitation.

Disadvantages of 3D printing stainless steel

While metal 3D printing has many advantages, there are also disadvantages that should be noted, including

Need 3D printing expertise

Modeling by metal 3D printing requires specialized know-how, such as knowledge of CAD software for creating modeling data and editing skills for data acquired from a 3D scanner.

In addition, because of the effects of heat during modeling, techniques are required to position the material appropriately according to the material.

Secondary machining is required when high-precision dimensions and surface roughness are required.

Secondary processing is required when a high level of dimensional accuracy or surface roughness is required for modeling.

For example, if you want to mirror-finish the surface of a part modeled in SUS316L, you must apply mirror-finishing in a secondary process after modeling with a 3D printer.

Not suitable for mass production in some cases

3D printers cannot model items that are too large to be produced outside the range of the table inside the printer.

Keep in mind that depending on the size of the object to be modeled, it may not be suitable for mass production.

How to choose a vendor for 3D printing of stainless steel

When requesting 3D printing of SUS316L from a vendor, there are many points that should be taken into consideration.

This section explains how to choose a vendor to remember for successful 3D printing of stainless steel.

Whether the company has extensive experience in 3D printing stainless steel

Some 3D printing companies only work with resin and not metal.

Be sure to ask a vendor that has experience in 3D printing stainless steel.

A contractor with extensive experience should have specialized skills and know-how in metal 3D printing.

Appropriate placement, design, etc. will be desired depending on the type of stainless steel and the molding.

Are other metal materials also supported?

Depending on the component or part to be manufactured, stainless steel other than SUS316L may be more appropriate.

If a company can 3D print other metal materials, you can expect not only a wider range of metals to choose from, but also more flexibility.

In particular, if you are unsure of the appropriate metal for the component you are considering modeling, it is a good idea to choose a vendor that supports 3D printing of a wide range of metal materials.

What is the delivery date?

Delivery time from request to delivery varies from vendor to vendor.

If you need the product delivered as quickly as possible, ask a vendor that can accommodate short delivery times.

Even if you are not in a hurry, confirming the approximate delivery date will help prevent problems such as late delivery.

How is the prototype finished?

If a company discloses the finished prototype on its official website, it will be easier to visualize the specific finish before commissioning.

If data such as dimensions of prototypes is also disclosed, we can know the technical capabilities of the vendor.

Checking the finished prototype will also help prevent mismatches between the finished product and the pre-commissioning process.

Does it support secondary processing?

Forming of stainless steel, including SUS316L, may require secondary processing in some cases.

If a vendor offers secondary processing, you can request 3D printing and secondary processing at the same time, saving you time and effort.

Summary

The features, merits and demerits of stainless steel SUS316L used for metal 3D printing, and cautions when using it for 3D printing were explained.

SUS316L is a stainless steel that can be 3D printed in addition to having excellent corrosion resistance.

On the other hand, since it is not a common material, it is necessary to consider material procurement and cost before proceeding with modeling.

Choose a vendor with extensive knowledge of 3D printing and stainless steel, as well as a proven track record, to ensure the success of your SUS316L modeling.

If you are considering manufacturing parts using 3D printing in stainless steel, please contact us.Taiga."Please make use of the following

Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742