Stainless steel is a material used in a wide variety of products, from everyday items to industrial products.

Sheet metal working of stainless steel is highly difficult, and the processing method must be selected according to the shape of the production.

In this article, we will explain in detail the methods and precautions for sheet metal working of stainless steel.

If you are considering requesting stainless steel sheet metal fabrication, please refer to this page.

For more information about Taiga, click here.Table of Contents

Stainless steel is one of the most difficult metals to fabricate sheet metal.

Stainless steel is an alloy made by adding chromium and nickel to iron.

Because of its high durability and resistance to rust, stainless steel is used as a material for a wide range of products, from machine parts to water-based housing equipment. Because of its hardness, stainless steel is a difficult material to process into sheet metal.

In addition, there are various types of stainless steel, and it is required to select a processing method according to its characteristics.

When requesting sheet metal processing of stainless steel, it is important to select a fabricator with knowledge and skills in the characteristics of stainless steel and appropriate processing methods.

Five methods of processing stainless steel sheet metal

The following five methods are available for sheet metal working of stainless steel.

- Cutting Process

- Bending Process

- Drilling Process

- Finishing and mirror finish

- Welding Process

The features, advantages and disadvantages of each processing method are explained.

Cutting Process

Cutting is a processing method to cut stainless steel sheet metal according to drawings.

Depending on the tools and methods used, the following types are available

- Shearing" cutting by pinching between upper and lower blades

- Press" to press the mold and cut out

- Laser" melts by applying laser light

- Plasma," which melts by injecting a jet of high-temperature plasma

- Water jet" cutting by spraying a high-pressure stream of water

Direct cutting of sheet metal allows stainless steel to be cut into desired shapes.

By combining other processing methods, it is also possible to create complex shapes of fabricated products.

However, because stainless steel is a poor heat conductor, it is necessary to devise ways to prevent heat from accumulating in the plate and tools during cutting.

Bending Process

Bending is a processing method for bending stainless steel sheet metal into the shape shown in the drawing.

There are various types of bending processes, including

- Die bending," in which a press machine is used to bend stainless steel sheet metal between dies

- L-bending while holding the edge of stainless steel sheet metal

- Forming bending" to bend the edges and ends of stainless steel sheet metal

- Feed bending (roll bending)" in which a stainless steel plate is continuously bent into a curved surface by applying pressure with a roller.

Generally, bending is performed using press machines, and by changing the shape of the die, it is possible to process into various shapes such as L-shape, V-shape, and cylindrical shape.

A press machine and a die that matches the shape must be prepared.

Drilling Process

Drilling is a process for making holes in stainless steel sheet metal.

Depending on the shape and number of holes to be drilled, use the following methods

- Drill with an edged drill to open it up.

- Drilling with a drill-mounted drilling machine

- Dissolve by spotting laser light

- Shot between upper and lower molds (punch)

By selecting the processing method, a variety of hole drilling processes are possible.

However, stainless steel is harder than other metals and has the characteristics of being stretchy, highly elastic, and prone to heat retention.

Therefore, it is important to note that drilling holes in the same manner as other metals will likely result in heat buildup in the material and tooling, and wear on the tooling.

Finishing and mirror finish

Finishing and mirror finishing is a process to prepare the surface of stainless steel sheet metal smoothly and beautifully.

The following methods are available for finishing and mirror finishing.

- Buffing," in which abrasives are applied to a disk-shaped tool (buff) made of layers of cloth, cotton, wool, etc., and rotated at high speed to polish the surface.

- Electropolishing," which uses electrolysis to melt and polish the surface of stainless steel sheets

- Hairline polishing": hairline scratches are made in a single direction to eliminate luster.

The advantage of the finishing/mirror finish process is that it can create a glossy or matte look.

Because of the advantage of easier surface treatment, finishing and mirror finishing are also applied to machine product parts.

Welding Process

Welding is a processing method of joining stainless steel sheet metals by melting them together.

Specifically, the following processing methods are available

- MIG welding," which uses inert gas as the shielding gas and a wire-like wire as the electrode

- TIG welding," which uses inert gas as the shielding gas and tungsten as the electrode

- Covered arc welding," which uses a stainless steel rod with a coated electrode

- Submerged arc welding," in which a coating material is applied to the joint and a wire, which serves as the electrode, is supplied.

- Resistance welding" uses resistance heat generated by applying pressure to stainless steel plates and energizing them.

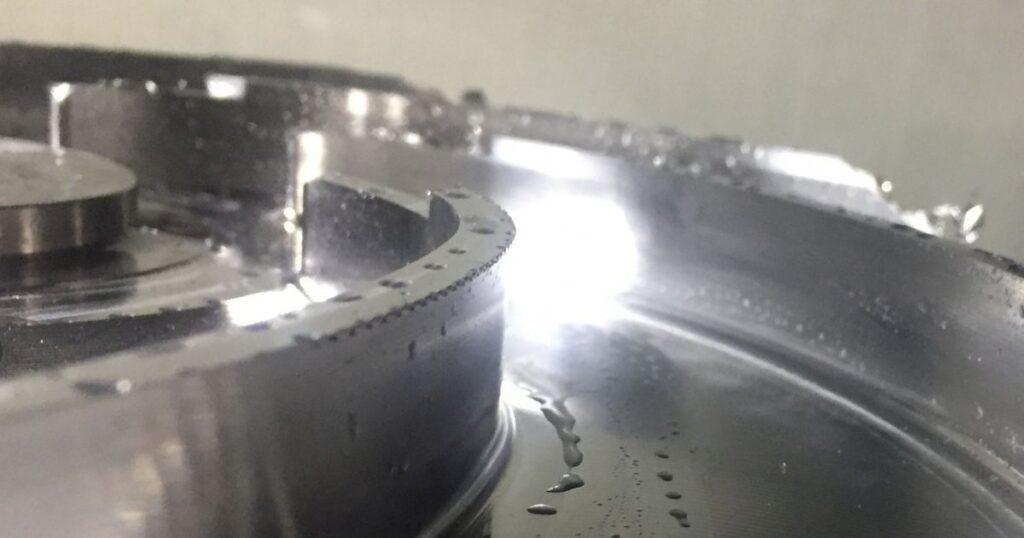

- Laser welding," in which a laser beam is irradiated to melt a localized area

Depending on the welding method, manual or automatic processing and the speed and finish of the welding process vary.

It is important to select a welding method that is appropriate for the type of stainless steel and the shape of the workpiece.

Types and characteristics of stainless steel used in sheet metal processing

There are three main types of stainless steel used in sheet metal processing.

- austenitic

- ferritic

- martensitic

The characteristics of each are described in turn.

austenitic

Austenitic stainless steel is stainless steel containing chromium (Cr) and nickel (Ni).

Because of its low cost and suitability for mass production, it is the most common stainless steel used in many products.

It also features excellent corrosion and heat resistance and high workability.

Although its hardness as a material is low, it becomes hard by heat treatment. Since it is not magnetic, it is also used as a material for automobile parts and parts for nuclear power generation and scientific equipment.

The main types of austenitic stainless steel are as follows

- 18-8 stainless steel

- SUS301L

- SUS304

- SUS310S

- SUS 316

- SUS430

ferritic

Ferritic stainless steel is basically nickel (Ni)-free stainless steel.

Major types include SUS430.

Ferritic stainless steel is magnetic and has higher hardness, heat resistance, and weldability than austenitic stainless steel. However, corrosion resistance is somewhat inferior.

It is mainly used as a material for household products.

martensitic

Martensitic stainless steel is stainless steel with low chromium (Cr) content.

Types such as SUS420 and SUS440 are available.

It has excellent strength, hardness, and abrasion resistance, and is magnetic, but its corrosion resistance is low.

It is utilized as a material for bearings and blades.

Points to note in sheet metal working of stainless steel

This section describes the precautions to remember in sheet metal working of stainless steel.

Different types of stainless steel sheets are suited to different processing methods.

Stainless steel is broadly classified into three types, which are further subdivided according to properties such as tensile strength, elongation, and hardness.

Corrosion resistance, heat resistance, and weldability vary depending on the type of stainless steel, so it is important to select an appropriate processing method.

Low thermal conductivity and easy to cure

Stainless steel is a metal with low thermal conductivity and is easily hardened by processing.

Therefore, burns, tool wear, and damage may occur during cutting and drilling operations.

During processing, it is necessary to take measures to prevent heat buildup in stainless steel sheet metal and tools.

Also, because of stainless steel's tendency to harden when a certain amount of force is applied, machining efficiency often deteriorates as machining proceeds.

For efficient machining, it is necessary to pay attention to the tools and machining conditions used and select appropriate ones.

Springback needs to be taken into account.

Springback is a phenomenon in which the elasticity of a material causes it to return to its original state.

Stainless steel has greater springback than other metals, so springback must be taken into account when bending.

Summary

We explained about sheet metal working of stainless steel, types of stainless steel, and precautions when sheet metal working of stainless steel.

While stainless steel is hard and resistant to corrosion, it is a difficult metal to process into sheet metal.

If you are considering manufacturing products by sheet metal working of stainless steel, choose a company that specializes in processing stainless steel.

If you are considering manufacturing parts utilizing stainless steel sheet metal fabrication, please contact us.Taiga."Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742