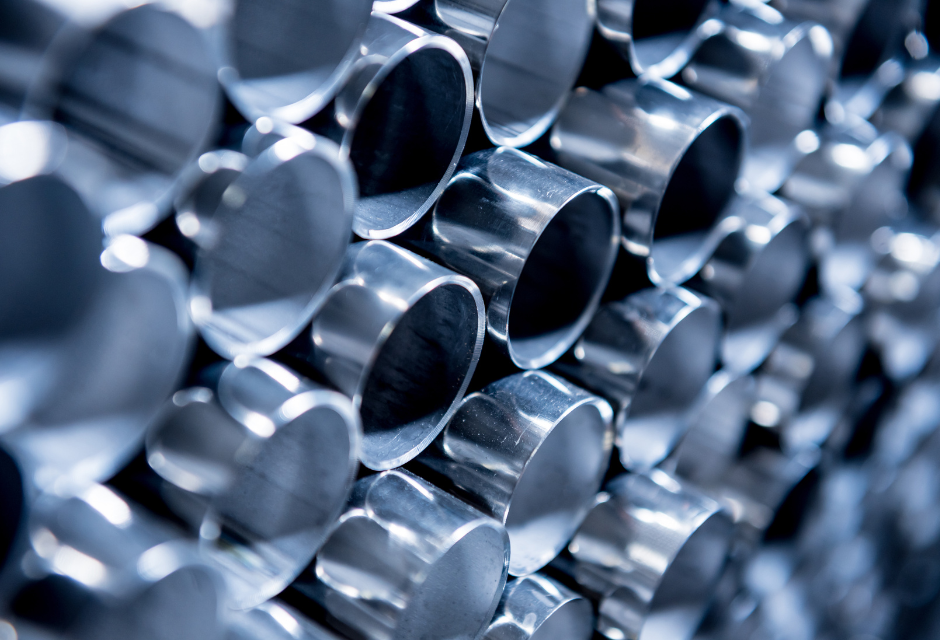

Stainless steel is a metal used in a wide variety of products, from household goods to medical equipment and aircraft parts.

There are several types of such stainless steels, each with very different characteristics.

In this issue, we will explain in detail the characteristics and typical types of stainless steel.

Please check it out for optimal material selection.

For more information about Taiga, click here.Table of Contents

What is stainless steel?

Stainless steel is an alloy steel with iron as its main component. In addition, it contains less than 1.2% carbon and more than 10.5% chromium.

Incidentally, the term "stainless steel" is used in English.

Stainless" means "rust-free" in Japanese, and was formerly called "non-stainless steel" or "fuseikou.

In addition, it is used in various products in our daily lives because it is not only rust-resistant but also very beautiful in appearance.

Some of you may be wondering about the difference between "stainless steel" and "stainless steel," but they are all the same in composition and characteristics, just called differently.

What are the typical types?

Let us now take a closer look at the typical types of stainless steel.

martensitic

Martensitic contains 0.1-0.4% carbon and 12-18% chromium.

It is extremely hard and is often used for machine parts.

In some cases, it is used for parts and machinery that are often exposed to high temperatures.

However, its relatively low carbon content makes it slightly less resistant to corrosion.

ferritic

Ferrite systems are resistant to corrosion against sulfur-containing gases.

Basically, it does not contain nickel.

It has excellent corrosion resistance and maintains its softness with little hardening even after heat treatment, making it suitable for press working.

It also has high workability and is often used for building interior materials and electrical appliance parts.

austenitic

Austenitic contains less than 0.15% carbon, 16-20% chromium, and more than 8% nickel.

Among the many stainless steels, this is the only one that contains nickel.

Because of its very high corrosion resistance and excellent weldability, it is often used for household items such as spoons and forks, automotive parts, and construction supplies.

However, it is not hardenable by heat treatment, and its altitude is inferior to that of martensitic grades.

bi-layer system

Bi-Layered is a stainless steel that is a cross between austenitic and ferritic.

It is sometimes used in seawater equipment and chemical plant equipment due to its superior resistance to seawater.

It is also an excellent material for magnetism, but its strength depends on the ratio of ferrite systems.

Advantages of Stainless Steel

The advantages of stainless steel are as follows

- High strength

- Excellent heat retention and heat resistance

- Clean in appearance.

Let's take a closer look at each of these.

High strength

Stainless steel is stronger than steel because of its carbon content.

In technical terms, it is sometimes described as "superior in rigidity.

However, strength depends on the presence or absence of heat treatment and the constituent elements.

Stainless steel, with its superior strength, is often used for parts that are critical to human life, such as jet aircraft engines and car brake discs.

Excellent heat retention and heat resistance

Chromium in stainless steel has excellent heat resistance.

All stainless steel can basically maintain its strength up to 500°C.

Stainless steel is also often used for water bottles and tumblers because of its extremely high thermal conductivity.

Clean in appearance.

Stainless steel is rust-resistant, yet clean looking.

It is also a material that conforms to food factory standards and is therefore often used for sinks.

It is also used in the interior design of buildings and other structures.

Disadvantages of stainless steel

Such stainless steel has the following disadvantages.

- Work-hardening properties.

- Low heat dissipation

Let's take a closer look at each of these.

Work-hardening properties.

Work hardening is a phenomenon in which a metal becomes harder when a certain amount of pressure is applied to it.

For example, when prototyping sheet metal parts in stainless steel, once bent, they become hard and difficult to reprocess, so they must be finished in one shot.

As for cutting and polishing, many companies dare to outsource these operations to specialized contractors because too much time spent on these processes can lead to work hardening.

Low heat dissipation

Low heat dissipation is another disadvantage of stainless steel.

When machining stainless steel, heat may be applied, which can put a load on the tool tip or cutting edge and shorten the tool's life.

However, this is the nature of stainless steel and cannot be helped.

For this reason, aluminum alloys are increasingly used in the design of mechanical parts around drive units.

Cautions for stainless steel

When utilizing stainless steel, the following points should be noted

- Biting phenomenon may occur

- Not absolutely rust-free.

Let's take a closer look at each of these.

Biting phenomenon may occur

The most important thing to watch out for with stainless steel is the bite phenomenon.

Biting phenomenon, in simple terms, refers to "seizure.

A common problem is the screw bite phenomenon.

Note that when tightened with an electric screwdriver, the male and female screws may adhere to each other and there is nothing that can be done about it.

To avoid such problems, it is necessary to use some ingenuity, such as coating or manually tightening the screws.

Not absolutely rust-free.

Stainless steel is a rust-resistant material.

However, it is not absolutely rust-free.

For example, note that exposure to strong acids or alkalis or extremely high humidity can lead to rust.

Taiga" for reliable manufacturing

If you are looking for a place to process stainless steel, Taiga is the place to go.

Taiga is a manufacturing matching service that provides a smooth manufacturing process.

We not only connect users and partners, but also support them in various aspects such as communication and information management.

Our engineers and technicians with cutting-edge technology and extensive experience in all fields are available to make proposals for the manufacture and development of complex-shaped parts and new parts,

We don't know the best way to manufacture them."

We'd like to try a different manufacturing method, but we don't have the in-house knowledge."

In the end, I don't know where to turn to for help."

It is also recommended for those who are worried about

In addition, to reduce the risk of unauthorized access, information leaks, and data tampering, we have introduced advanced security measures to ensure that confidential information is well protected.

If you are at all interested, please feel free to contact us.

Summary

Stainless steel is an alloy steel with iron as its main component.

There are several types, all of which are strong and have excellent heat retention and heat resistance.

In addition, because of its clean appearance, it is often used for daily necessities.

Processing such stainless steel requires specialized knowledge and skills.

If processing cannot be done in-house, it will inevitably be outsourced to an outside vendor.

However, it is surprisingly difficult to find a suitable client for your company, and some of you may be struggling to choose the right client.

If so, take advantage of Taiga, a matching service for manufacturing companies offering safe and reliable manufacturing.

For more information about Taiga, click here.

0120-987-742

0120-987-742