Titanium has excellent strength, corrosion resistance, and light weight, and is used in 3D printing for manufacturing a variety of products.

For example, in aerospace, it is used to reduce the weight of rocket and airplane components, and in medicine, it enables the manufacture of implants designed for each patient.

This article describes the materials used in titanium 3D printing, including their characteristics, types, and recommended 3D printers.

For more information about Taiga, click here.Table of Contents

Titanium is a major material in metal 3D printing

Titanium is one of the major materials in metal 3D printing.

Its light weight, high strength, and excellent corrosion resistance make it suitable for a wide range of applications.

It is particularly suited for products that require high performance, such as aerospace, medical equipment, and industrial products.

Types of titanium used for 3D printing

The types and characteristics of titanium used for 3D printing are as follows

| Material Name | feature | Main applications |

| Titanium 6Al-4V (Grade 5) | Lightweight, high strength, corrosion resistant; most common titanium alloy for 3D printing | Used to reduce component weight and improve durability in the aerospace and automotive fields |

| Titanium 6Al-4V (Grade 23) | Biocompatible material suitable for the medical field | Medical implants, prosthetics and patient customized products |

| Titanium Beta 21S | Excellent strength, oxidation resistance, and creep resistance | Special applications for aircraft engines and medical equipment |

| Pure titanium (Cp-Ti, Grade 1 and 2) | Highly biocompatible and compatible with the human body | Medical field (implants, surgical tools) |

| TA15 | Near-alpha titanium alloy with high specific strength, load-bearing capacity, and temperature resistance | Aircraft parts, engine manufacturing, etc. |

Understanding the properties and applications of titanium materials will help you get the most out of titanium in 3D printing.

Scenes in which titanium is used for 3D printing

Because of its high strength, light weight, and excellent corrosion resistance, titanium is used in the following applications

- luxury wristwatch: Capable of producing watches with intricate designs and luxurious textures.

- medical equipment: Utilized as a material for custom implants and surgical tools

- high-performance bicycle: Lightweight and stronger, also utilized in the manufacture of racing frames

- Consumer Electronics: Can be used in components such as smartphones and VR goggles to reduce weight and increase durability.

Common to all of these areas is the need for design, light weight, and durability.

Because titanium can meet these needs, it is used in a wide range of situations.

Advantages of using titanium for 3D printing

The advantages of using titanium for 3D printing are threefold

- High strength and corrosion resistance

- Components can be made lighter

- Low thermal conductivity and non-magnetic

Each will be explained.

High strength and corrosion resistance

Titanium is a lightweight metal with high strength and corrosion resistance.

For this reason, they are used in the manufacturing industry, where durability is required, as well as in medical and electronic device components.

It is also often used as a material for cooking utensils and fishing equipment because of its resistance to salt water.

Components can be made lighter

Titanium is an ideal material for weight reduction of products because of its high strength yet light weight.

With a specific gravity of 4.7 g/cm³, it is lighter than iron and copper, and light weight can be achieved simply by replacing parts that previously used other metals with titanium.

As a typical example, titanium material is used in the iPhone 15 pro, which is designed to be approximately 20 g lighter than the previous iPhone 14 pro model.

Low thermal conductivity and non-magnetic

Titanium is a non-magnetic material with low thermal conductivity.

It is mainly used as a material for the following environments and products

- High temperature environment: Engine parts

- Environment susceptible to magnetic fields: inside MRI machine

- Human body contact in the medical field: medical devices and implants

Its low thermal conductivity makes it ideal for manufacturing products that require high thermal insulation as described above.

It is also a non-magnetic material that is not affected by magnetic forces and is often used in the manufacture of medical devices and other equipment used inside the body.

How to 3D print titanium

3D printing of titanium is mainly performed using the powder bed method.

There are three main types of powder bed systems: laser powder bed fusion (LPBF), electron beam powder bed fusion (EB PBF), and DED.

Let's look at each of these below.

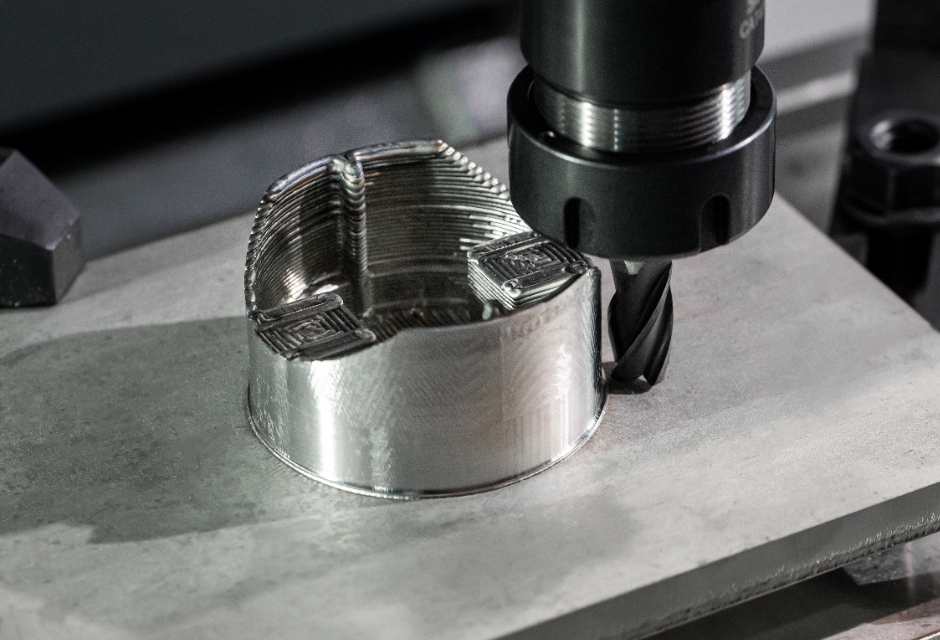

Laser Powder Bed Fusion (LPBF)

Laser Powder Bed Fusion (LPBF) is a technology that creates parts by layering metal powders while melting them with a high-powered laser.

By setting processing conditions such as laser power and powder layer thickness that match the characteristics of the material, the density and finish of the part, as well as its final strength and performance, can be adjusted.

This makes it possible to produce high-precision and durable parts.

Electron Beam Powder Bed Fusion (EB PBF)

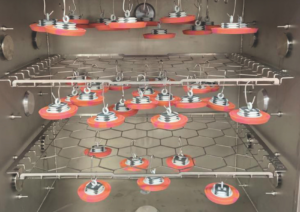

Electron beam powder bed fusion (EB PBF) is a manufacturing technique that differs from LPBF in that it uses an electron beam as the energy source.

Electron beams have very high energy and can melt metal powders at high temperatures.

As a result, the speed at which the metal cools after processing is slow, and the inside of the finished metal may be a little rough.

However, the higher temperatures used for molding make it easier to increase strength, and it is also possible to process large materials. For this reason, it is widely used for aircraft parts and industrial equipment.

Four titanium-compatible 3D printers

Here are some recommended 3D printers that are compatible with titanium.

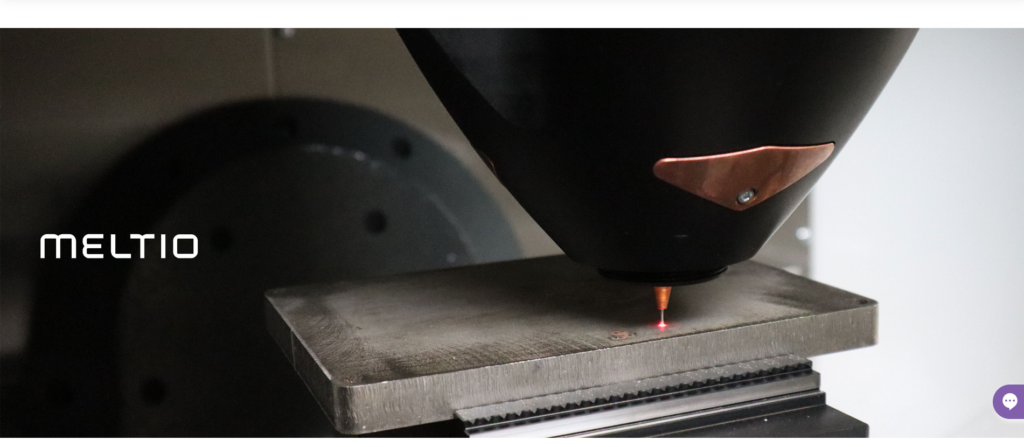

Meltio M450

The Meltio M450 is a wire DED metal 3D printer with all the necessary features.

It is titanium-compatible, easy to use, and anyone can start modeling right away.

It can produce small- to medium-sized moldings that are stronger than forgings, making it ideal for research and development of bimetallic products. It is also safe and requires no extensive peripheral equipment or protective gear.

It is especially recommended for companies and educational institutions that are introducing metal 3D printers for the first time.

| Manufacturer | Meltio S.A. |

| Price | inquiry |

JAM-5200EBM

The JAM-5200EBM is a high-performance electron beam 3D printer from JEOL.

In addition to a high output of up to 6 kW, it is equipped with a long-life cathode that lasts more than 1,500 hours, ensuring stable processing performance.

The product finish is enhanced by the ability to heat the powder bed to a temperature of up to 1,100°C or higher and by "e-Shield," a feature that prevents powder from scattering.

This 3D printer has an extensive track record in the aerospace and medical fields and is suitable for manufacturing precision parts and highly durable products.

| Manufacturer | JEOL (JEOL) |

| Price | inquiry |

Dmp Flex 100

The Dmp Flex 100 is a high-precision metal 3D printer from 3D Systems.

A surface finish of up to 5 Ra μm is possible, resulting in a very smooth surface finish on metal parts. The advantage is that even the corners can be made beautifully, so less rework is required after machining.

In addition, the patented layer compression technology enables accurate modeling of fine designs and thin areas.

In addition to time and cost savings, this 3D printer is suitable for manufacturing complex parts.

| Manufacturer | 3D Systems |

| Price | Approx. 30 million yen |

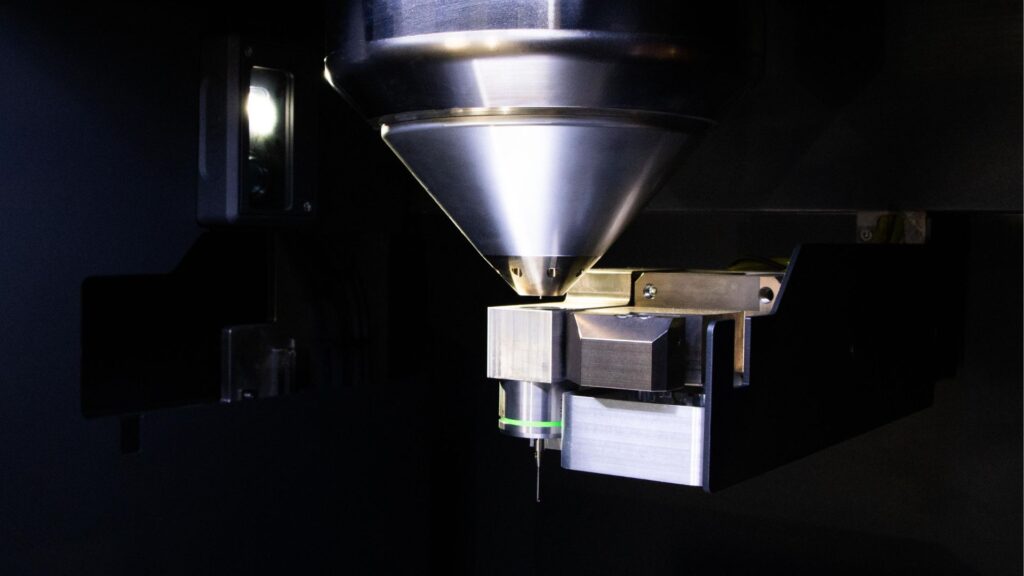

Lasermeister 100A Series

The Lasermeister 100A series is a metal 3D printer developed by Nikon Corporation based on the concept of "easy for anyone to use.

The machine is equipped with a "3D alignment function" that automatically adjusts the position of parts to be machined, which is expected to save a great deal of preparation work. Furthermore, the 5-axis mechanism enables metal modeling in any shape.

Adding new processing to existing parts or repairing broken parts is easy, and repairs can be made without the need to replace parts, which is expected to reduce costs and waste.

| Manufacturer | Nikon Corporation |

| Price | inquiry |

Summary

3D printing of titanium is widely used in the aerospace and medical fields, taking advantage of the titanium material's high strength, light weight, and corrosion resistance.

In addition, there are a variety of titanium-compatible 3D printers available, but all are expensive to install.

To achieve efficient and high quality products, it is advisable to select and consult with the appropriate processors.

If you are considering manufacturing parts using 3D printing, please contact us! Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742