There are a variety of lathe turning methods available, depending on the size of the workpiece to be machined. Among them, large lathe turning is an option when considering machining large objects.

However, some people who are considering manufacturing or machining products on a large lathe may have questions such as, "What size products can be machined on a large lathe?" Many of them may have questions such as, "What is the accuracy of the machine used and the finished product?

In this article, we will discuss the characteristics of large lathe machining, the machining tools used, and the advantages and disadvantages of this process.

We also introduce how to select a contractor for large lathe machining, so please refer to this page.

For more information about Taiga, click here.Table of Contents

What is large lathe machining?

Large-scale lathe processing is lathe processing to finish items with a diameter of 300 or more, or more specifically, items that are too large to be held in both hands.

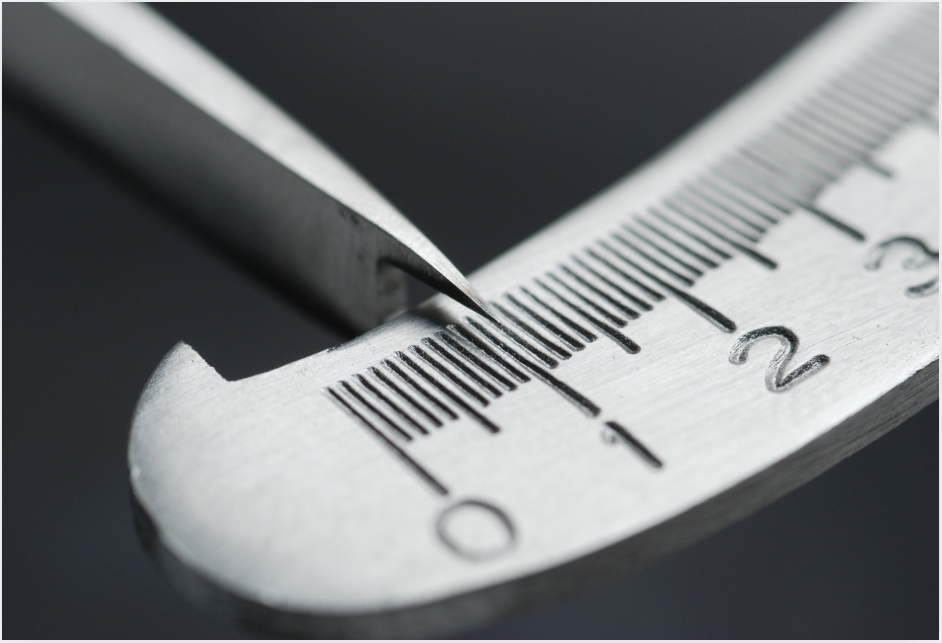

Lathe turning is a machining process in which a fixed tool is applied to a material while rotating it, and is used to manufacture and machine cylinders and other round-shaped objects.

Although large lathe turning is less precise than small lathe turning, it is possible to achieve a certain degree of accuracy by properly adjusting the material thinness and size and selecting a machine specifically designed for large lathe turning.

Processing machine used in large lathe machining

Large-scale lathe machining involves the use of machining equipment such as vertical lathes (turning) and horizontal lathes (front lathes).

Here we explain the features of each processing machine.

Vertical lathe (turning)

A vertical lathe is a machine that places materials on a rotary table with a vertical axis of rotation and performs turning operations from above with a fixed tool.

Even relatively large sized materials can be fixed more stably than with a horizontal lathe.

The advantage is that it also reduces the effects from vibration and distortion caused by changes in the center of gravity and centrifugal force, and it can achieve higher machining accuracy than horizontal lathes.

Fixing the machine to the table makes it possible to proceed with processing in a stable manner and reduces the possibility of human error.

Horizontal Lathe (Front Lathe)

Horizontal lathe is a turning method in which the material is installed vertically (horizontally).

Horizontal lathes are not suitable for machining large materials, so vertical lathes are generally used for large lathe work.

On the other hand, horizontal lathes have the advantage that chips are less likely to be generated and stable machining can be performed over a long period of time, so horizontal lathes are sometimes used according to the size and properties of the material.

Advantages of Using a Vertical Lathe (Turning) in Large Lathe Machining

This section describes the main advantages of using a vertical lathe for large lathe operations.

High-precision machining

The advantage of the vertical lathe is that it can be stably fixed to the rotary table using the dead weight of the workpiece.

Since even large workpieces can be stably rotated, the machine is less prone to gravity and centrifugal force jolts than a horizontal lathe, and will be able to achieve highly accurate machining.

In addition, the vertical lathe allows the operator to view the entire workpiece from the top.

This makes it easy to grasp the state of the workpiece and tool movement during machining, and to make adjustments as necessary, thus increasing machining accuracy.

Easy chucking

The vertical lathe has the advantage that the material can be fixed stably to the table, and the material can be tightened and fixed (chucked) to the faceplate more easily than with a horizontal lathe.

The ease of chucking allows for efficient high-precision lathe machining.

Efficiency can be improved by milling process

In addition to turning, some vertical lathe processing machines (turning centers) are equipped with a milling function that performs cutting while rotating the tool.

The advantage of this is that once the material is fixed to the machine, multiple processes such as turning and cutting can be performed simultaneously.

Processes such as material removal and re-fixing are shortened, leading to shorter overall machining lead times and more efficient operations.

Disadvantages of vertical turning in large lathe machining

While there are advantages to large lathe turning using a vertical lathe, there are also disadvantages.

Here are the disadvantages you should be aware of, in order.

Inability to process long and small diameter objects

Vertical lathes have the disadvantage that they are not suitable for machining long or small-diameter objects due to their structure.

Specifically, the lack of a centering table prevents the suppression of deflection and chatter that occurs during the machining of long workpieces.

Furthermore, the faceplate of the machining table of the vertical lathe and the center of the spindle do not have a cylindrical hole, so when using the chuck, the depth can only be obtained within the chuck size range, making it difficult to stably fix a long object.

Chip evacuation process is required during machining

When machining a stop hole or the like on a vertical lathe, it is important to note that chips will accumulate deep in the hole.

Continued machining with chips left at the back of the hole may cause scratches or deformation to the material or damage to the tool.

When performing large turning operations on a vertical lathe, it is important to proceed with the machining based on the chip evacuation process.

Requires know-how and skills unique to vertical lathes (turning)

Achieving high-precision large lathe turning with a vertical lathe requires know-how and skills that are unique to vertical lathes.

For example, some vertical turning machines are capable of milling, but to perform both vertical turning and milling at the same time requires both machining know-how and programming skills.

Note that while vertical lathe machines can achieve a wide variety of machining, such as high-precision machining and complex shapes, through program control, they require specialized knowledge and skills.

Main applications and industries utilizing large lathe machining

The ability to manufacture and process large-sized products and parts in large lathe turning operations is often utilized in the following areas and products

- Industrial equipment in the petroleum, chemical, and energy fields (rotating elements, generators, etc.)

- Aircraft and ship components (turbines, gears, shafts, discs, cases, etc.)

- medical equipment

How to choose a contractor for large lathe machining

For large lathe machining, we will ask a specialist to perform the machining.

This section provides step-by-step instructions on how to select a contractor for large lathe machining.

Do you have the equipment to handle large lathe operations?

Large-scale lathe machining requires specialized machining equipment, including vertical turning machines.

Be sure to request a supplier that has the right machine and equipment for the characteristics, shape, and size of the material you wish to process.

The vendor's official website may list the features of the actual processing machines used and the specific processing details that can be achieved.

In addition, considering work efficiency and cost, a vertical lathe machine that can also handle milling operations or a horizontal lathe machine may be more appropriate.

Make sure that the facilities and equipment are appropriate for the products and shapes you want to achieve with the large lathe.

Do you have experience in processing the product you wish to request?

Large-scale lathe machining can achieve a variety of shapes and sizes.

However, the type of products that can be processed depends on the vendor.

A supplier with experience in processing the shape and details of the process you want to make will have the high technology and expertise to tackle the process.

Summary

Along with the features, merits and demerits of large lathe machining, we have explained the cautions for large lathe machining and how to choose a vendor.

Large lathe machining is suited for machining items larger than a pair of hands, and vertical lathes are particularly suitable for stable material placement and high precision machining.

Based on the shape of the product or part you actually want to make and other factors, choose a supplier with high technology and a proven track record to perform the processing.

If you are considering manufacturing parts utilizing CFRP processing, please contact us.Taiga."Please make use of the following

Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742