Services Offered by Taiga

We are a one-stop shop for the entire 3D printing process, from design and development to manufacturing, post-processing, and quality control. For 3D printing processing, leave it to Taiga.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >3D printing is a technology that forms three-dimensional objects by layering resin materials based on digital data. Instead of cutting out materials as in the conventional cutting process, materials are layered only in the necessary areas, enabling objects with complex shapes to be formed in one piece. This technology is used for various applications such as prototype production, small-lot production, and customization, because it enables speedy molding of objects with complex shapes that have been difficult to produce with conventional processing methods.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >Since there is no need for initial investments like molds, prototypes can be produced at a low cost and in a short period of time. The process is also flexible, allowing for easy design changes, and repeated prototyping and improvements can accelerate the development of better products. At Taiga, we are also flexible in accommodating design changes and secondary processing.

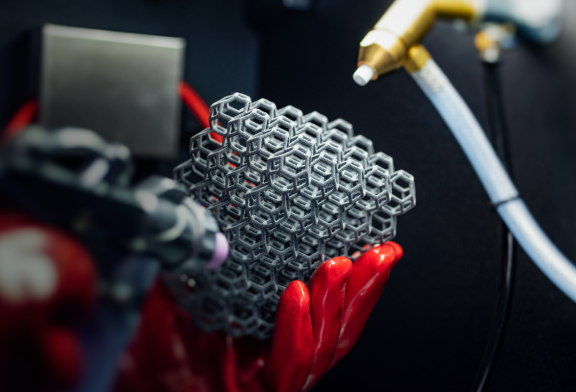

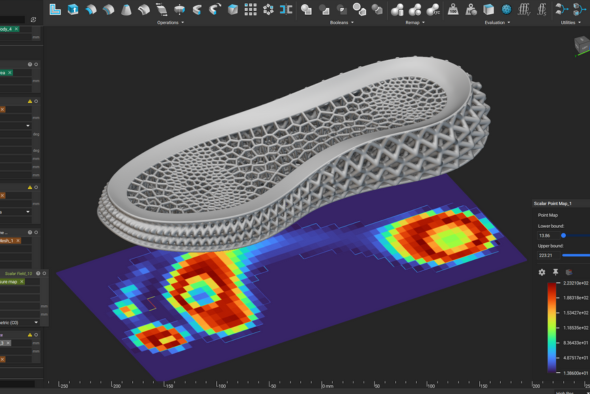

3D printing enables the creation of complex shapes and internal structures that are difficult to achieve with traditional machining or injection molding. It is ideal for creating lightweight parts with hollow structures, intricate lattice designs, and customized medical implants tailored to individual body types, making it easy to handle complex designs and customization.

Compared to traditional manufacturing methods, the process can simplify production steps. This leads to reduced lead times, labor costs, and inventory management expenses.

Since material is only layered where needed, material waste is minimized, making the process more resource-efficient.

The shape and specifications of the part to be 3D printed are determined, and a 3D model is created using 3D CAD software, etc. On the Taiga, the part to be corrected or checked on the drawing can be written in real time and shared with the project members as they work.

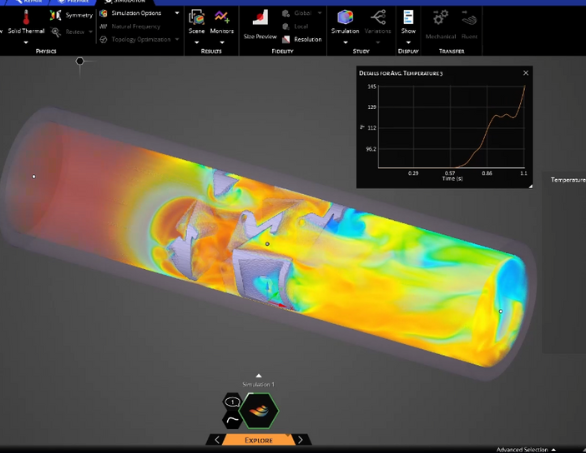

We prepare for printing by converting the 3D model into the appropriate data, slicing it into thin layers for the additive process, and setting parameters such as fill density.

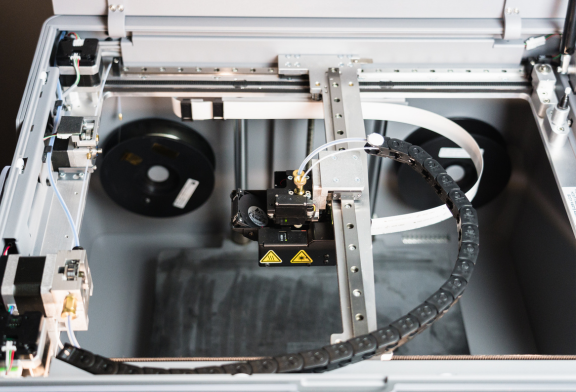

Once the preparations are complete, the 3D printer starts modeling. Based on the slice data, the material is layered.

Post-processing tasks such as removing support material, surface treatment, and assembly are performed as needed.

The completed object undergoes inspection to ensure that its dimensions, shape, and strength meet quality standards. After these steps, the 3D printed item is finished.

Developed parts and products are stored on Taiga, making it easy to reprocess (or re-purchase) the same items when needed.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

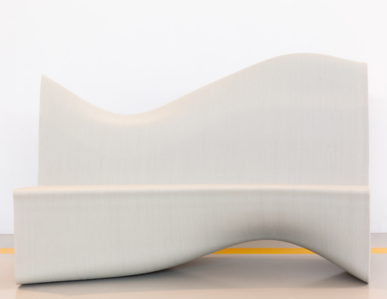

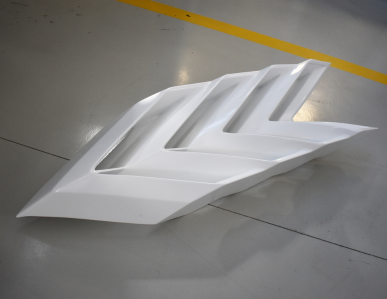

LFAM (Large Format Additive Manufacturing) is an additive manufacturing technology that uses large-scale thermoplastic materials. By extruding resin in pellet form and layering it, large parts can be created as a single piece, resulting in seamless, high-strength structures. Compared to traditional molding methods, LFAM reduces material waste and enables faster prototyping and production. It is widely used in industries such as aerospace, automotive, maritime, and design. Additionally, LFAM is suitable for using recycled materials, making it a sustainable choice that aligns with environmental considerations.

SLA (Stereolithography) is a high-precision layered molding technology using liquid resin. By curing photosensitive resin with ultraviolet laser irradiation, extremely smooth and precise parts can be modeled. It is widely used in the automotive, medical, dental, prototype modeling, and design fields because of its superior ability to reproduce minute details and thin-walled structures. Because it can achieve higher dimensional accuracy and surface quality than other 3D printing technologies, it is increasingly being used for prototypes and master models that are close to the final product.

SLS (Selective Laser Sintering) is a 3D printing technology in which powdered materials are sintered by laser irradiation and stacked layer by layer to form a three-dimensional object. It does not require support materials and is suitable for modeling parts with complex shapes and internal structures, and is used not only for prototyping but also for manufacturing final products. It is particularly strong in the modeling of functional parts that require heat resistance and chemical resistance, and is used in a wide range of fields including aerospace, automotive, medical, and industrial machinery.

FDM (Fused Deposition Modeling) is a 3D printing technology in which thermoplastic resin is heated to melt and extruded through a nozzle to form layers. The technology can also be used for parts that require high strength, heat resistance, chemical resistance, and other properties. It is used not only for prototyping, but also for a wide range of applications such as jigs, welding fixtures, and final parts.

Vapor Smoothing is a surface treatment technology that smooths out unevenness and roughness between layers by applying a special solvent vapor to the surface of 3D printed resin parts. The vapor slightly melts the surface and smoothes out the unevenness of the surface layer, resulting in a shiny and smooth finish. In addition to improving texture and appearance, it also contributes to waterproofing, airtightness, and resistance to stains and chemicals. It is often used for applications that require the appearance quality of industrial products and for post-treatment of moldings that are intended to be used as end products.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

We provide a one-stop solution for the entire 3D printing process, from design and development to material preparation, processing, and post-processing. Additionally, the data for the finished parts or products is stored on Taiga, making it easy to re-purchase with just one click.

We consistently support high-precision and high-quality manufacturing processes by utilizing the latest equipment and the expertise of our engineers cultivated over many years.

At Taiga, we offer a variety of services designed to achieve more efficient manufacturing.

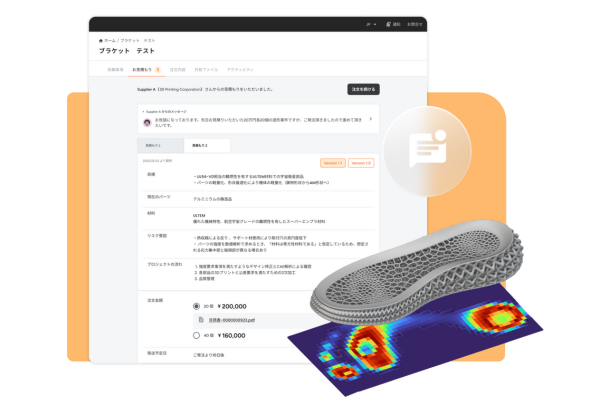

First, we provide a "collaboration feature" that allows all project stakeholders to view and approve drawings and contracts in real-time.

Additionally, our platform enables easy communication through chat, and consolidates various files—such as 2D and 3D drawings, quotes, and project-related documents—into one central location.

These services help meet the diverse needs of our customers, streamline information sharing, and improve efficiency by reducing inspection time, returns, and rework.

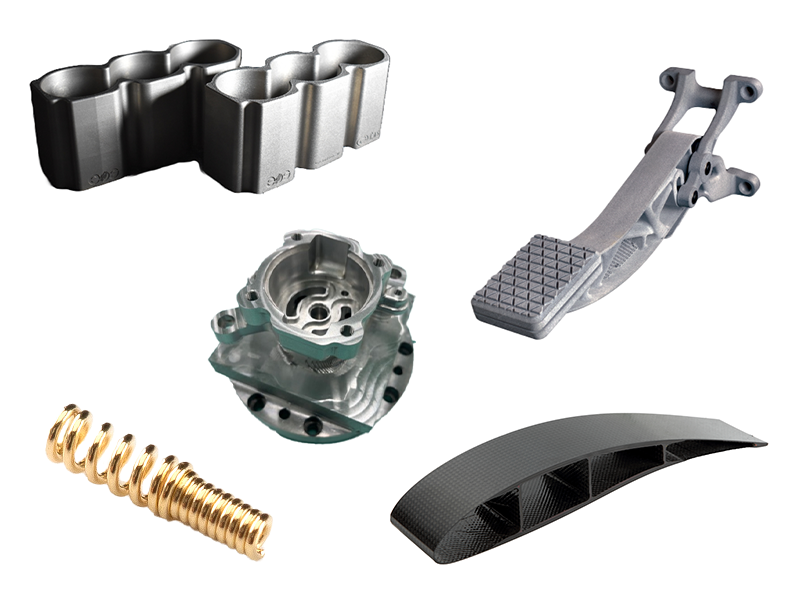

In addition to 3D printing, we also support a variety of manufacturing methods, including sheet metal fabrication, injection molding, machining, and CFRP processing. We propose multiple optimal manufacturing solutions for your products, helping to reduce the time spent searching for subcontractors. This ensures fast quotations and smooth parts production.

Sign Up

Contact us to request a registration form, and our team will help you get started.

Upload Your Design

Submit your drawings and project requirements through the platform.

Get Technical Proposals

Receive detailed proposals from multiple companies with advanced technical expertise.

Compare and Collaborate

Use Taiga’s built-in chat and drawing tools to review and discuss proposals with each company.

Place Your Order

Once you’ve chosen the best proposal, place your order directly through Taiga and start production.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Taiga collaborates with companies that possess advanced processing technologies to deliver the most suitable technical proposals for your needs. Receiving proposals from multiple companies for a single project expands your options and allows you to compare different approaches. By evaluating construction methods, costs, and delivery times, you can choose the most efficient and balanced solution. All participating companies have a proven track record in manufacturing and have built trusted relationships with Taiga’s operator, 3D Printing Corporation, over many years. Our flexible system supports highly specialized technologies, helping to reduce the time and effort required for technical research and vendor selection.

You can view the details of each technology.

Procurement Barrier Looms in Shipbuilding Repairs In shipbuilding repair and refurbishment, procurement of a wide variety of small-volume components and large steel structures frequently [...]...

Alex (Interviewer): Mr. Suzuki, thank you for sitting d [...]

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)

Dear Sir or Madam, We hope that all is well with you at this time. We would like to take this opportunity to thank you for your continued support. We would like to take this opportunity to [...].

Taiga supports all manufacturing methods besides 3D printing.

Our experienced engineers equipped with state-of-the-art technology will propose the best manufacturing method to meet your requirements.