Services Offered by Taiga

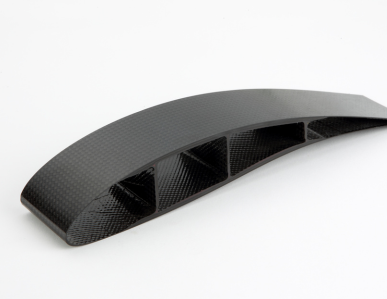

CFRP processing is essential for achieving both lightweight and high-strength properties. At Taiga, we use advanced precision processing techniques to deliver high-quality CFRP components for the aerospace and automotive industries. We can handle complex shapes and offer flexible solutions, from prototyping to mass production.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

CFRP processing involves shaping CFRP (carbon fiber reinforced plastic) into the desired form. CFRP is used in a variety of industries, including aerospace, automotive, and sporting goods. Known for its excellent properties—lightweight, high strength, and high rigidity—CFRP can be challenging to work with due to its hardness. At Taiga, we offer a one-stop solution for CFRP processing, which demands a high level of technical expertise.

No information entry required!

Download >Please feel free to contact us for production consultation!

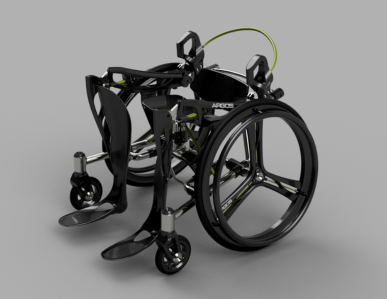

Contact >CFRP is lightweight yet offers superior strength and rigidity compared to steel or aluminum. As a result, products made through CFRP processing are ideal for structural components that require both high strength and rigidity.

CFRP is much lighter than metal materials such as steel and aluminum. Consequently, products made from CFRP processing contribute significantly to weight reduction.

CFRP allows for precise control over fiber orientation and stacking configurations. This enables CFRP processing to easily create products with complex shapes or three-dimensional geometries.

CFRP does not rust or corrode like metallic materials. Therefore, products made through CFRP processing are well-suited for use in harsh environments, such as outdoors or underwater.

First, determine what product or part you want to create and create the design blueprint. Drawings can be created and edited on Taiga. You can use the pen, highlight, typing, and chat functions to collaboratively edit 2D drawings in real time, making corrections or clarifications as needed.

Based on the design, we prepare the necessary CFRP materials. CFRP is available in various forms, including prepreg (resin-impregnated carbon fiber sheets), carbon fiber fabric, and carbon fibers. We also prepare core materials and molds as needed.

After preparing the materials, they are formed into the desired shape. The main molding methods are as follows:

・Autoclave Molding

This method involves laminating prepreg into a mold and curing it by heating and pressurizing in an autoclave (heating and pressurizing furnace).

・RTM Molding

In this method, carbon fiber fabric is placed in a mold, resin is injected, and it is then cured.

・Press Molding

This method involves laminating prepreg or SMC (sheet molding compound) onto a die, then heating and pressurizing it in a press machine to cure.

・Filament Winding Molding

This method involves winding carbon fibers around a mandrel while impregnating them with resin and curing the material.

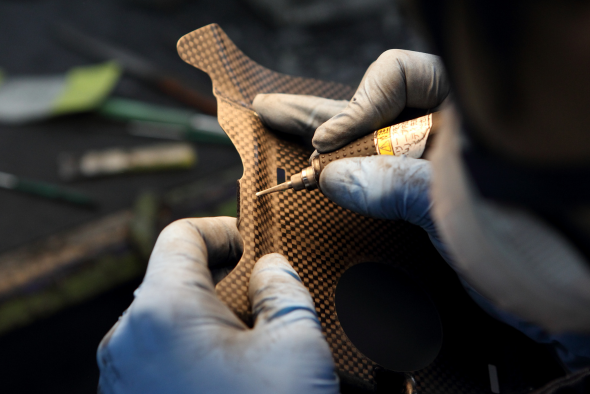

Molded CFRP is processed into the designed shape. Taiga supports a variety of machining methods, including cutting, laser machining, and water jet machining.

We perform processes such as deburring, surface treatment, and painting to enhance the appearance of the product or part. Surface treatments include plating, painting, and anodizing, which are selected based on the product’s application and requirements.

The finished products are inspected for size, shape, appearance, and strength to ensure they meet quality standards. After these processes, the CFRP product is complete.

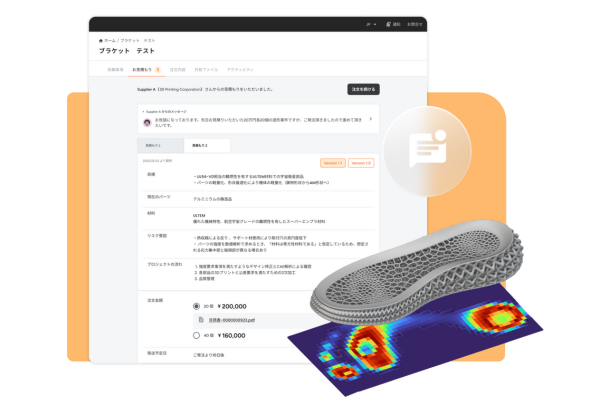

Developed parts and products are stored on Taiga, making it easy to reprocess (or re-purchase) the same items when needed.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Prepreg laminate molding is a processing technique where "prepreg sheets," which are carbon fibers impregnated with resin, are stacked and then heated and pressurized to cure. By arranging the sheets in multiple layers and adjusting the orientation of the fibers, high-strength, high-rigidity composite materials can be molded. This method is primarily used in industries requiring high strength and lightweight materials, such as aerospace, automotive, and sporting goods. The heating and pressurization processes using autoclaves or hot presses enable high dimensional accuracy and excellent mechanical properties.

Autoclave molding is a forming technique that cures composite materials in a high-temperature, high-pressure environment. Prepreg (resin-impregnated fiber sheets) are layered in a mold and sealed in a vacuum bag. The sealed mold is then heated and pressurized inside an autoclave, allowing for the creation of high-density, bubble-free parts. This method is particularly suitable for the manufacturing of parts that require excellent mechanical properties, such as those in aerospace, automotive, and sporting goods industries. It achieves uniform curing and excellent fiber content, making it widely used for the production of high-strength, high-rigidity CFRP (carbon fiber reinforced plastic) components.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Taiga handles the entire CFRP processing workflow, from design and material preparation to various molding techniques, machining, and finishing. Additionally, data for completed parts and products are stored on Taiga’s platform, making it easy to reorder with just one click.

We consistently support high-precision and high-quality manufacturing processes by utilizing the latest equipment and the expertise of our engineers cultivated over many years.

At Taiga, we offer a variety of services designed to achieve more efficient manufacturing.

First, we provide a "collaboration feature" that allows all project stakeholders to view and approve drawings and contracts in real-time.

Additionally, our platform enables easy communication through chat, and consolidates various files—such as 2D and 3D drawings, quotes, and project-related documents—into one central location.

These services help meet the diverse needs of our customers, streamline information sharing, and improve efficiency by reducing inspection time, returns, and rework.

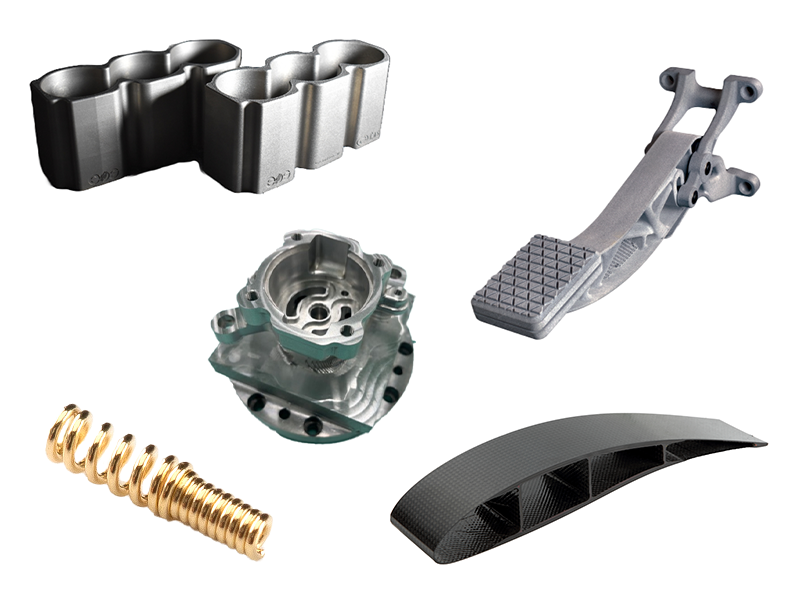

In addition to CFRP processing, we also support a variety of manufacturing methods, including sheet metal processing, 3D printing, cutting, and injection molding. We offer multiple manufacturing options best suited for your product, saving you the time and effort of sourcing external partners. With fast quotations and smooth parts production, we ensure quick and efficient results.

Sign Up

Contact us to request a registration form, and our team will help you get started.

Upload Your Design

Submit your drawings and project requirements through the platform.

Get Technical Proposals

Receive detailed proposals from multiple companies with advanced technical expertise.

Compare and Collaborate

Use Taiga’s built-in chat and drawing tools to review and discuss proposals with each company.

Place Your Order

Once you’ve chosen the best proposal, place your order directly through Taiga and start production.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Taiga collaborates with companies that possess advanced processing technologies to deliver the most suitable technical proposals for your needs. Receiving proposals from multiple companies for a single project expands your options and allows you to compare different approaches. By evaluating construction methods, costs, and delivery times, you can choose the most efficient and balanced solution. All participating companies have a proven track record in manufacturing and have built trusted relationships with Taiga’s operator, 3D Printing Corporation, over many years. Our flexible system supports highly specialized technologies, helping to reduce the time and effort required for technical research and vendor selection.

You can view the details of each technology.

Procurement Barrier Looms in Shipbuilding Repairs In shipbuilding repair and refurbishment, procurement of a wide variety of small-volume components and large steel structures frequently [...]...

Alex (Interviewer): Mr. Suzuki, thank you for sitting d [...]

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)

Dear Sir or Madam, We hope that all is well with you at this time. We would like to take this opportunity to thank you for your continued support. We would like to take this opportunity to [...].

In addition to CFRP machining, Taiga also offers a full range of other manufacturing methods.

Our experienced engineers equipped with state-of-the-art technology will propose the best manufacturing method to meet your requirements.