Services Offered by Taiga

Leveraging precision cutting, bending, and welding techniques, we work with a wide range of metal materials. From automotive parts to machinery components and enclosures for precision equipment, we can process any shape with speed and high accuracy.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Sheet metal fabrication is the process of cutting, bending, punching, and joining thin metal sheets to create various shapes. This technique is used in many products we encounter in daily life, including:

・Home Appliances: Refrigerators, washing machines, air conditioners, etc.

・Office Equipment: Copiers, fax machines, computers, etc.

・Automobiles: Body parts, bumpers, mufflers, etc.

・Buildings: Exterior walls, roofs, doors, etc.

Sheet metal fabrication has several advantages, including the ability to create complex shapes, excellent mass production capabilities, high strength and durability, and the potential for lightweight designs. It is an essential technology used across a variety of industries.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >In sheet metal fabrication, metal materials are plastically deformed to maintain or increase their inherent strength.

Sheet metal fabrication uses thin metal sheets to reduce product weight.

Sheet metal processing can produce products with complex shapes by combining various processing methods such as cutting, bending, and welding.

Sheet metal processing can efficiently mass-produce products of the same shape by using dies and jigs.

First, we decide what kind of product or part to create and prepare the design drawings. Drawings can be created and edited on Taiga. Using tools like pen, highlight, typing, and chat features, everyone can edit 2D drawings simultaneously, making it easy to correct or clarify any areas.

Based on the design, we cut the metal sheets to the required size. Various methods are used for cutting, including laser cutting, shearing machines, plasma cutting, and waterjet cutting. Taiga’s ability to handle all types of cutting processes is one of its key features.

We bend the metal sheets into the desired shape using machines such as a press brake. Important factors in the bending process include angle, bending radius, and precision.

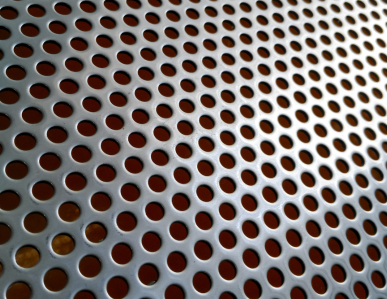

Using drills or punching machines, we create holes in the metal sheets. The size, position, and shape of the holes are determined according to the design drawings.

We join multiple metal sheets by welding them together. There are various welding methods, including arc welding, spot welding, and laser welding, all of which Taiga supports. The strength and finish of the welds greatly impact the product’s quality, requiring skilled technicians for proper execution.

We perform processes such as deburring, surface treatment, and painting to enhance the appearance of the product or part. Surface treatments include plating, painting, and anodizing, which are selected based on the product’s application and requirements.

Multiple parts are combined to assemble the final product.

The finished product is inspected for dimensions, shape, appearance, and strength to ensure it meets quality standards. After these processes, the sheet metal fabrication is complete.

Developed parts and products are stored on Taiga, making it easy to reprocess (or re-purchase) the same items when needed.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Laser processing is a technology used to cut and shape metal sheets by directing a high-energy laser beam at the material. With a precise laser beam, it’s possible to cut complex shapes and perform fine, detailed work. Because the process is non-contact and does not require traditional cutting tools, it produces a smooth finish with minimal distortion and burrs. It can be applied to a wide range of materials, including steel, aluminum, and stainless steel, making it a versatile solution used across various industries.

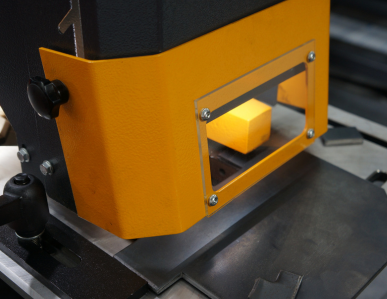

NC bending is a technology that allows for precise bending of metal sheets using numerical control (NC). A machine known as a press brake is used, where the angle and shape are controlled via a die and program. This allows for high-precision bending, which is difficult to achieve manually, and ensures consistent quality even during repetitive processing. Automation has enhanced production efficiency, and this process is widely used in industries such as precision sheet metal fabrication and chassis manufacturing.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

We provide a one-stop solution for the entire sheet metal fabrication process, from design and various types of processing to finishing and assembly. Additionally, the data for completed parts and products is stored on Taiga, allowing for easy re-purchase with just one click.

We consistently support high-precision and high-quality manufacturing processes by utilizing the latest equipment and the expertise of our engineers cultivated over many years.

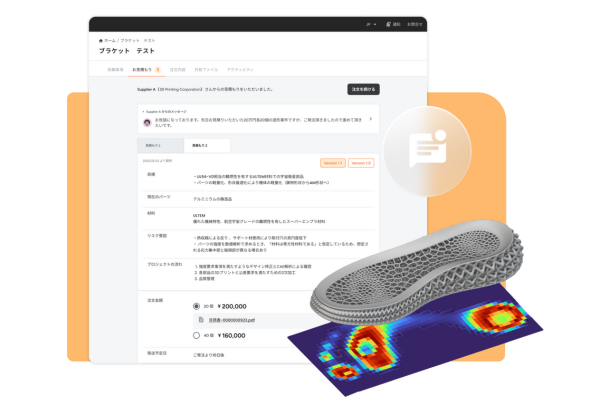

At Taiga, we offer a variety of services designed to achieve more efficient manufacturing.

First, we provide a "collaboration feature" that allows all project stakeholders to view and approve drawings and contracts in real-time.

Additionally, our platform enables easy communication through chat, and consolidates various files—such as 2D and 3D drawings, quotes, and project-related documents—into one central location.

These services help meet the diverse needs of our customers, streamline information sharing, and improve efficiency by reducing inspection time, returns, and rework.

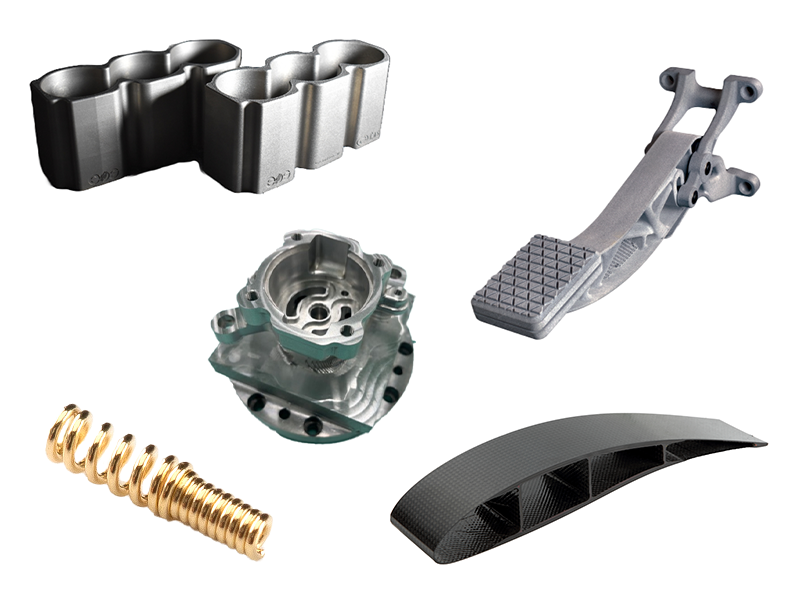

In addition to sheet metal processing, we also support various manufacturing methods such as CFRP processing, 3D printing, cutting, and injection molding.

We propose multiple manufacturing methods best suited for your products, reducing the time and effort required to search for subcontractors. We provide quick quotations and smooth parts manufacturing.

Sign Up

Contact us to request a registration form, and our team will help you get started.

Upload Your Design

Submit your drawings and project requirements through the platform.

Get Technical Proposals

Receive detailed proposals from multiple companies with advanced technical expertise.

Compare and Collaborate

Use Taiga’s built-in chat and drawing tools to review and discuss proposals with each company.

Place Your Order

Once you’ve chosen the best proposal, place your order directly through Taiga and start production.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Taiga collaborates with companies that possess advanced processing technologies to deliver the most suitable technical proposals for your needs. Receiving proposals from multiple companies for a single project expands your options and allows you to compare different approaches. By evaluating construction methods, costs, and delivery times, you can choose the most efficient and balanced solution. All participating companies have a proven track record in manufacturing and have built trusted relationships with Taiga’s operator, 3D Printing Corporation, over many years. Our flexible system supports highly specialized technologies, helping to reduce the time and effort required for technical research and vendor selection.

You can view the details of each technology.

Procurement Barrier Looms in Shipbuilding Repairs In shipbuilding repair and refurbishment, procurement of a wide variety of small-volume components and large steel structures frequently [...]...

Alex (Interviewer): Mr. Suzuki, thank you for sitting d [...]

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)

Dear Sir or Madam, We hope that all is well with you at this time. We would like to take this opportunity to thank you for your continued support. We would like to take this opportunity to [...].

In addition to sheet metal fabrication, Taiga can handle all other manufacturing methods.

Our experienced engineers equipped with state-of-the-art technology will propose the best manufacturing method to meet your requirements.