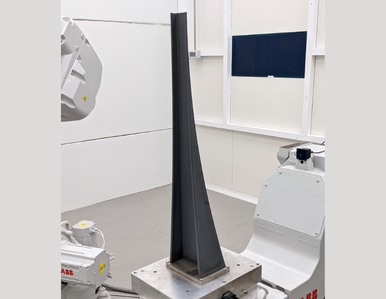

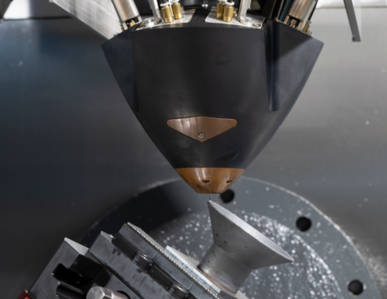

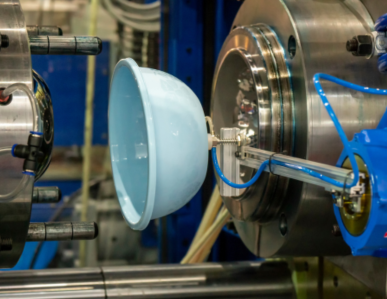

CFRP

CFRP processing technology is used in the construction industry to produce lightweight, high-strength components. Typical applications include structural materials for reinforcement, floor and wall panels, earthquake-resistant reinforcement plates, handrails and posts, and repair members for bridges and buildings. CFRP is far lighter than metal, yet has excellent rigidity and corrosion resistance, contributing to reduced burden during construction and improved long-term durability. CFRP is particularly effective at sites where reinforcement of existing structures or construction in narrow spaces is required, and is attracting attention as a next-generation construction material.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)