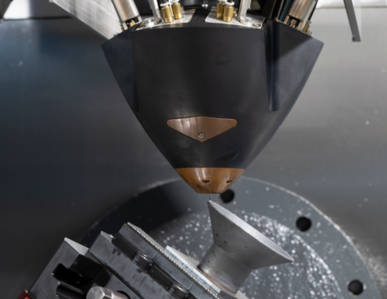

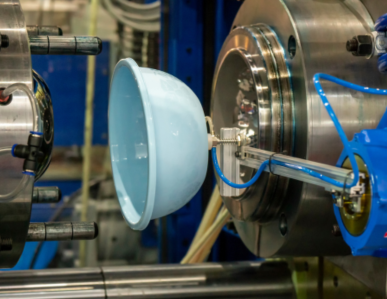

CFRP

CFRP processing is widely used in drone manufacturing to reduce weight and achieve high rigidity. In particular, CFRP is used in the manufacture of parts such as frames, arms, propellers, landing legs, and camera mounts, enabling improvements in flight time and mobility by reducing the overall weight of the airframe. CFRP also has higher specific strength than metal and is resistant to vibration and impact, leading to highly precise flight control and stability. It also has excellent corrosion and fatigue resistance, making it an ideal material for use outdoors and in harsh environments.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)