CFRP

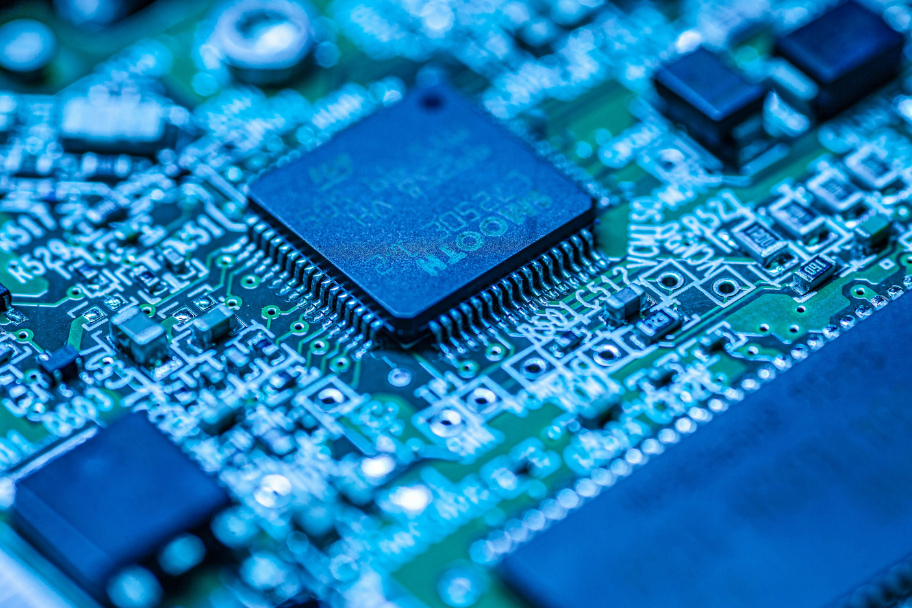

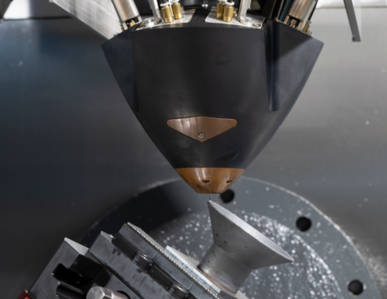

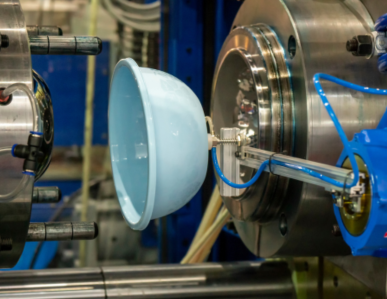

CFRP processing technology is used in electronics and semiconductor manufacturing to achieve lightweight and highly rigid components. For example, CFRP is used in the manufacture of housing parts for precision equipment, arms for transport equipment, frames and stages for mounting equipment, and parts used in static-sensitive environments. CFRP is lighter than metal and has superior vibration damping and dimensional stability, making it ideal for manufacturing electronic devices and semiconductor components that require minute movements and high-speed processing. It also has chemical resistance and non-magnetic properties, making it suitable for use in clean environments.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)