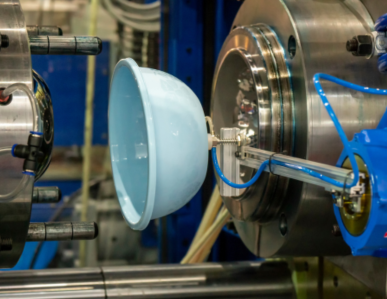

CFRP

CFRP processing technology is utilized in furniture and lighting manufacturing to reduce weight and achieve high design quality. CFRP is especially used for chair and table legs, shell-shaped seating surfaces, lighting stands, and pendant light shades, enabling the manufacture of products with a unique texture and strength. CFRP is lighter, more rigid, and more durable than metal, making it suitable for manufacturing stylish and practical design furniture. It can also be used to create curved surfaces and thin-walled structures, which is difficult with conventional materials, and is attracting attention as a material that broadens the scope of spatial presentation.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)