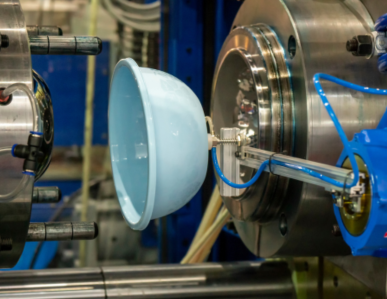

Cold Forming Process

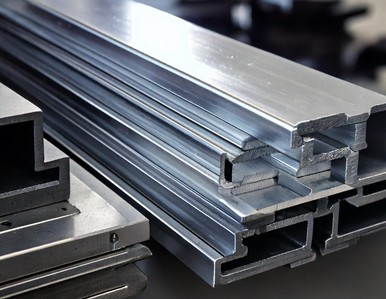

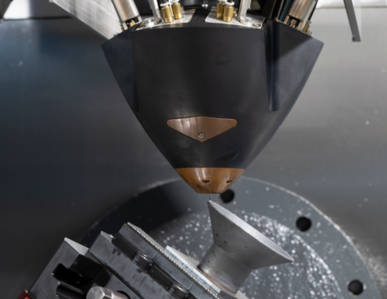

Cold working is a processing method that causes plastic deformation of materials below their recrystallization temperature and can be utilized in the manufacture of parts for industrial equipment.

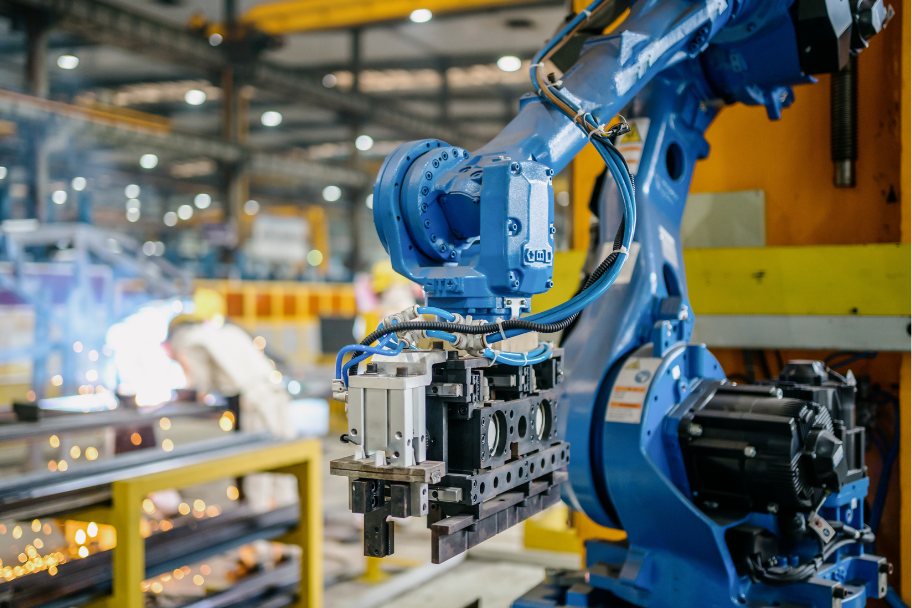

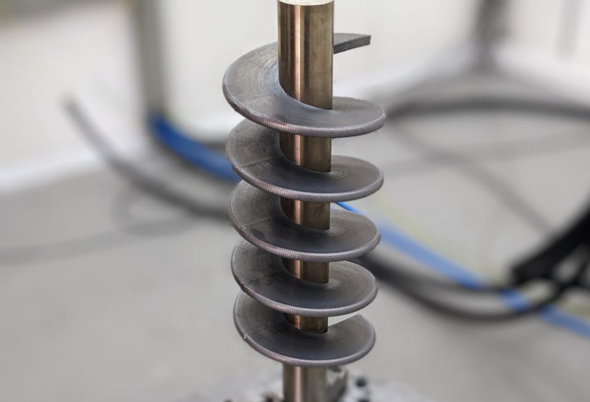

It is used in the manufacture of automotive engine parts, gears, bolts, nuts, connectors for electronic devices, micro gears, other precision parts, bearings, gears, and shafts for industrial machinery, and many other parts.

Cold working is important in the field of industrial equipment parts manufacturing, where weight reduction and improved durability are required, because work hardening increases the strength of the material.

At the same time, it offers various advantages, such as precise dimensional accuracy, making it suitable for manufacturing parts with complex shapes, and smooth surfaces, contributing to improved fatigue strength and corrosion resistance.

Furthermore, cold working is a processing method suitable for mass production, enabling efficient manufacturing of industrial equipment parts.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)