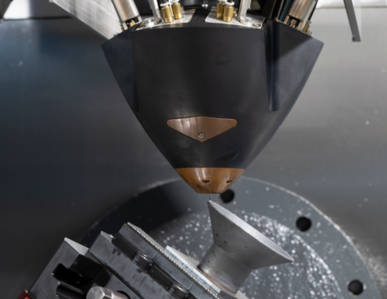

Cold Forming Process

Cold working is a processing method that plasticizes materials below their recrystallization temperature, and is widely used in the manufacture of medical parts.

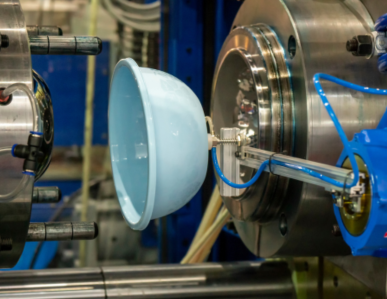

The medical field requires precise and safe parts that conform to the patient's body. Cold working is an effective means of meeting these requirements.

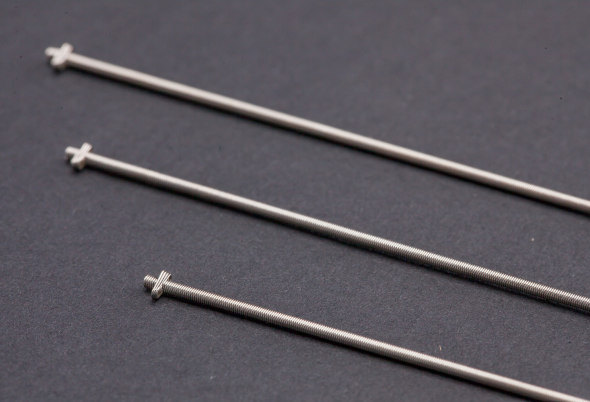

Cold working is widely used in the manufacture of artificial joint parts, dental implants, and surgical instruments.

Cold working is important in increasing the strength of medical and prosthetic components because work hardening increases the strength of the material.

At the same time, it also provides various advantages, such as precise dimensional accuracy, making it suitable for manufacturing parts with complex shapes, and smooth surfaces, improving hygiene and patient comfort in medical device parts.

Furthermore, it can also be used to process materials with high biocompatibility (compatible for use in the human body), such as titanium and stainless steel.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)