CFRP

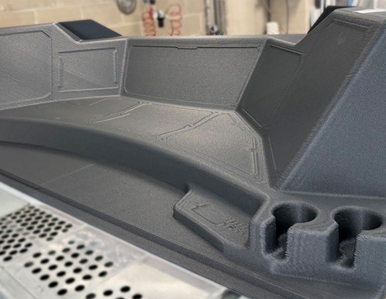

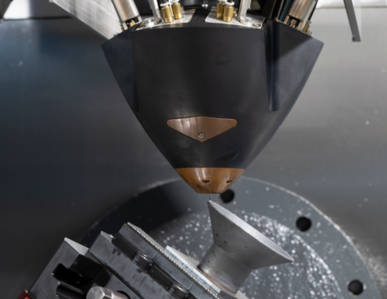

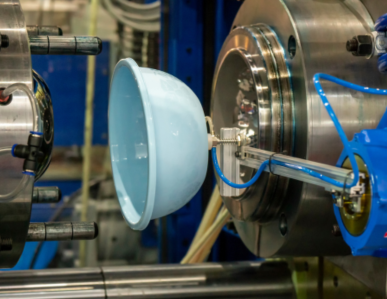

In CFRP processing, the manufacture of parts using recycled materials is also progressing. CFRP scrap recovered from aircraft and automobiles is crushed, reprocessed, and reused as recycled CFRP, making it possible to manufacture highly functional parts while reducing environmental impact. Typical applications include bicycle parts, sporting goods, covers for home appliances, and reinforcement panels for building materials. By recycling waste materials while maintaining the excellent moldability and specific strength characteristics, sustainable manufacturing that contributes to a recycling-oriented society will be realized.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)