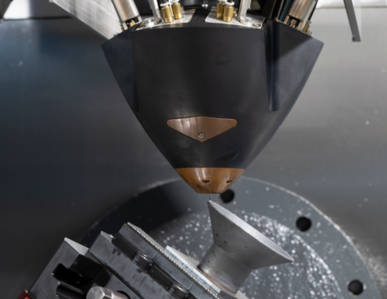

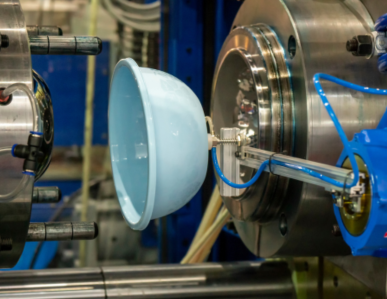

CFRP

CFRP processing is a processing technology utilized in the shipbuilding industry to reduce weight and increase strength. CFRP is significantly lighter than metal, is resistant to corrosion, and has excellent resistance to fatigue and salt damage, contributing to improved fuel efficiency and durability of ships. Recently, CFRP has been increasingly used, especially for radar masts, partial hull structures, hatch covers, inboard stairs, and railings. It is also attracting attention as a material that broadens the range of design possibilities because of its high degree of freedom in processing and its ability to be used for parts with complex shapes.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)