CFRP

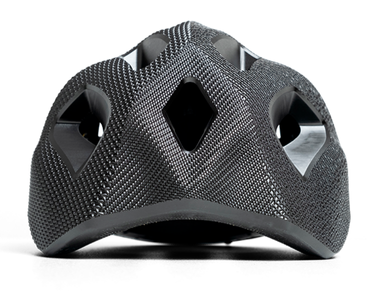

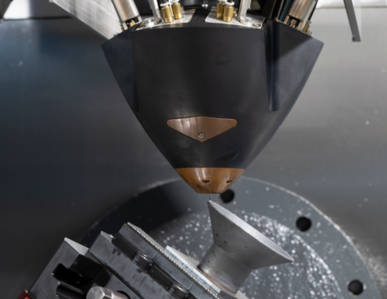

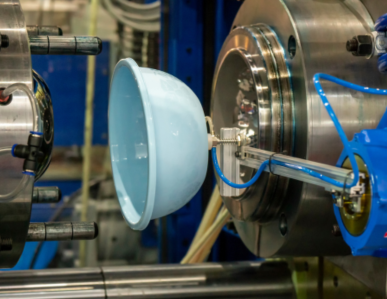

CFRP processing is an indispensable processing technology in the manufacture of sports and outdoor products to achieve lightweight and highly rigid parts. Typical parts using CFRP processing include bicycle frames, tennis rackets, golf club shafts, trekking poles, and helmet shells. CFRP is significantly lighter than metal and has equivalent or superior strength and impact resistance, which allows for improved mobility and portability. It also has excellent corrosion and fatigue resistance and is suitable for long-term use, making it particularly valuable in the manufacture of professional and high-end products.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)