Table of Contents

Obsolete Parts Procurement" Wall Looming for Gas and Oil Plants

Many gas and oil plants have long-life equipment that can continue to operate for more than 30 years. At the same time, however, manufacturers are discontinuing parts one after another, and the problem of not being able to obtain necessary parts is becoming more serious.

Even a single missing part can lead to equipment stoppages and risk huge cost losses. This article describes this issue of procurement of obsolete parts and its solution.

For more information about Taiga, click here.Main issues in procurement of obsolete parts

1. difficult to obtain due to manufacturer's discontinuation

Plant equipment is used for decades, but manufacturers often stop manufacturing parts after a few years, and replacements may not exist.

2. special specifications that cannot be used with commercially available alternatives

There are few commercially available products that meet the unique requirements of gas and oil plants, such as pressure and heat resistance and special dimensions.

3. risks of overseas procurement

Attempts to import from overseas can result in delivery times of several months and the risk of nonconformance due to differences in standards.

4. losses due to equipment shutdowns

If operations are halted because necessary parts are not available, the entire plant's production will be affected and losses will be enormous.

Conventional solutions and their limitations

So far, the following measures have been taken

Search the used market and warehouse inventory

Special order requests to manufacturers

In-house fabrication for alternative production

However, in many cases, fundamental solutions have not been reached because the required quantities are not available, the production line itself has disappeared, or there is a lack of processing equipment or human resources.

Taiga offers new solution for procurement of obsolete parts

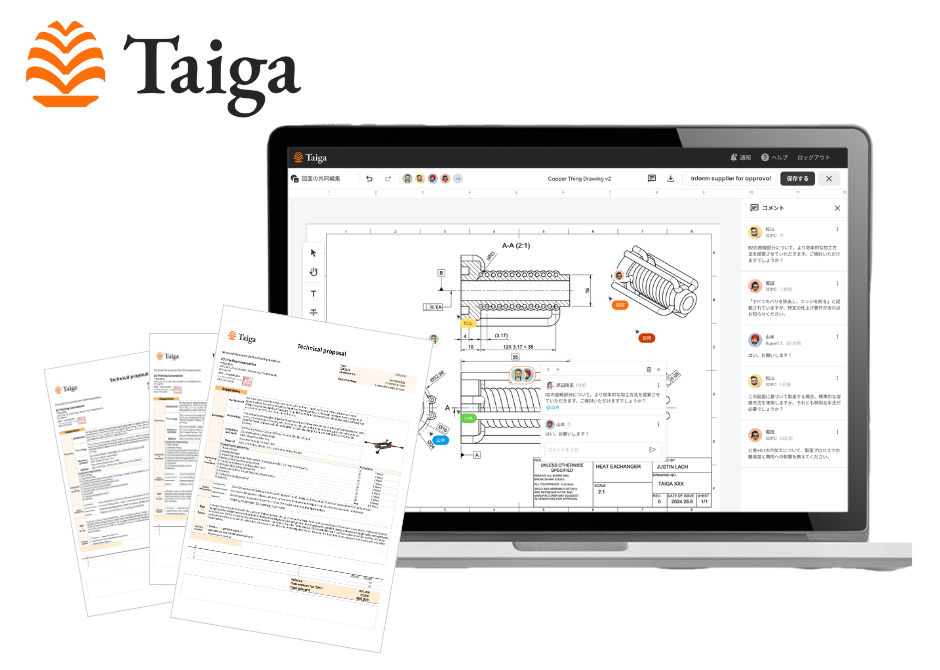

Taigais a digital platform built to solve the procurement challenges of the manufacturing industry. For gas and oil plants, it solves end-of-life parts issues through the following approaches

1. reverse design (reverse engineering)

3D scanning of existing parts and reconstruction of design data. We can manufacture parts for which drawings do not exist or parts that are more than a decade old.

2. extensive manufacturing network

We cover a wide variety of manufacturing methods, from metal fabrication, casting, precision machining, and 3D printing. We re-create parts using the most appropriate methods.

3. Expert Suggestions for Improvement

Taiga features more than just "rebuilding" obsolete parts.

By reviewing manufacturing methods from an expert's perspective,

Reduction of procurement time

Cost Reduction

This could have the potential to produce additional positive effects, such as extending the life of components.

4. short delivery times and small lot sizes

We can respond to requests for "just one item" or "in a hurry. We support quick procurement without interrupting plant operations.

5. quality assurance and reliability

We have established a quality control system compliant with ISO standards and supply parts that can be used with confidence.

Advantages of using the Taiga

- Significantly reduces the risk of equipment outages

- Shorter delivery time and cost optimization than overseas procurement

- Extends component life and enables long-term operation of the entire facility

- Database of manufactured parts enables continuous procurement system to be established.

Case Study: Remanufacturing Rotary Screw Parts

Item:Rotary screw

Dimensions: ø 50 mm, 75 x 75 x 230 mm Weight: 2.55 kg

Material: SUS316L coated on SUS304 round bar

Formation time: 7 hours 23 minutes

Conventional manufacturing: Cutting

Since they were manufactured by cutting them from thicker rods, procurement time was required and there was a large amount of wasted material due to cutting.

↓arrow (mark or symbol)

Changed manufacturing method to metal 3D printer

The manufacturing time could be significantly reduced because the product could be directly modeled on a round bar. In addition, 3D printing has made it possible to manufacture with only the necessary amount of material.

Summary

The "out-of-date parts procurement issue" in gas and oil plants is an unavoidable challenge.

Now that conventional methods alone have their limitations, Taiga can eliminate the risk of missing products and support stable plant operations.

0120-987-742

0120-987-742