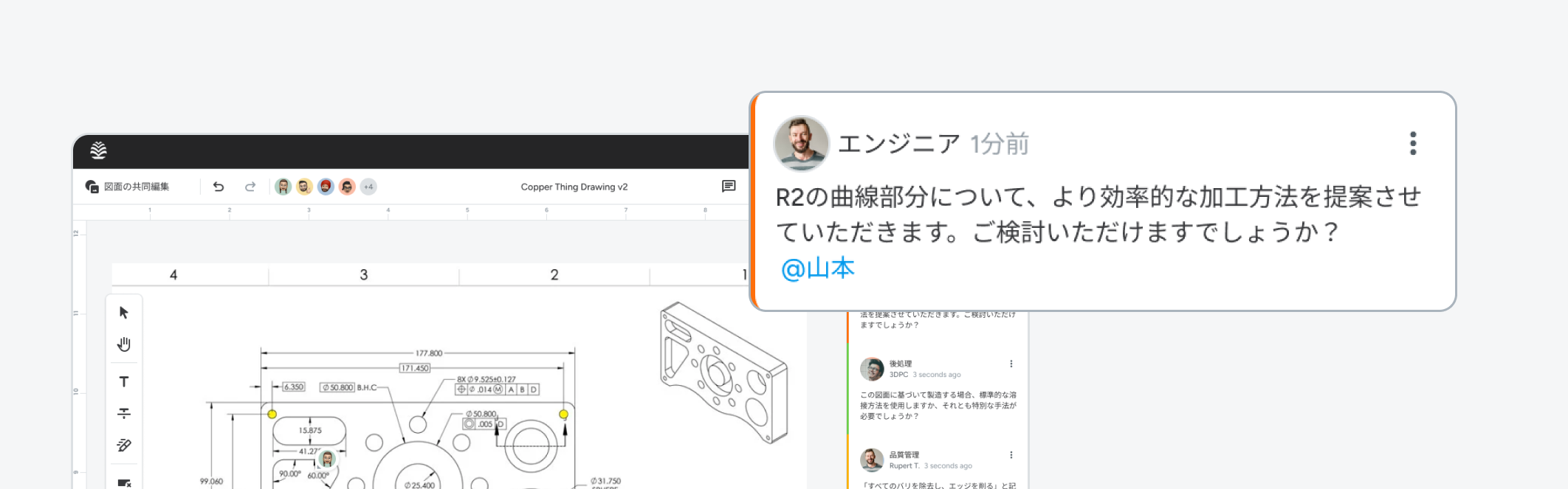

Taiga combines 3D printing with traditional manufacturing methods like CFRP processing, sheet

metal fabrication, and injection molding.This hybrid approach enables the creation of complex,

high-performance parts that deliver both durability and precision.It’s a flexible solution that

supports both R&D prototyping and mass production needs.

By combining the latest technology with conventional technology, we provide products with superior durability and performance, even for complex and sophisticated components that cannot be made using only conventional manufacturing methods.

This integration of technology is critical to meeting the diverse needs of the manufacturing industry, and can serve both the R&D department, which makes prototypes, and the procurement department, which produces large quantities of products.

0120-987-742

0120-987-742