Services Offered by Taiga

Cold forming is a high-precision technique that can accommodate complex shapes and small production runs. Taiga provides fast turnaround times and high-quality processing to meet a wide range of customer needs.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Cold forming is a processing method where metal is shaped at room or low temperatures, without the need for heating it to high temperatures. It is widely used in the manufacturing of springs, as it maximizes the material properties of the metal and allows for the creation of precise shapes and dimensions.

In cold forming, metal wires or sheets are subjected to processes such as pressing, extrusion, and bending to achieve the desired shape. This technique enhances the strength of the parts and improves dimensional accuracy, making it ideal for components like springs, which require both durability and precision.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >Cold forming minimizes metal distortion while ensuring exceptionally high dimensional accuracy. It is especially suitable for the manufacturing of springs that require precision at the micron level.

By utilizing cold forming, we can manufacture springs with complex shapes that would be difficult to produce using traditional methods. It enables high-precision bending and cutting, making it adaptable to a wide range of shapes.

Cold forming is particularly well-suited for small-lot production and prototypes. We offer flexible solutions to meet your required delivery timelines and can quickly accommodate design changes.

Thanks to its high processing precision, cold forming reduces the need for additional finishing and post-processing, leading to cost savings. It is also suitable for mass production, offering excellent cost efficiency.

Decide on the shape and specifications of the parts to be processed using cold forming, and create design drawings. With Taiga, you can create and modify design drawings in real-time, allowing for an efficient workflow.

Select the appropriate metal (such as steel or aluminum) for cold forming and verify the required dimensions and properties. Proper material selection directly impacts the final product's quality.

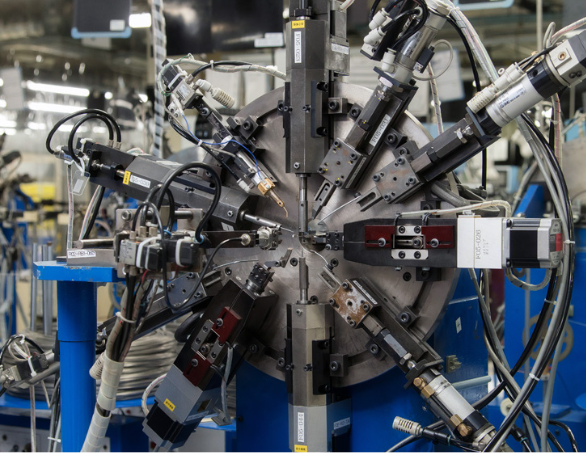

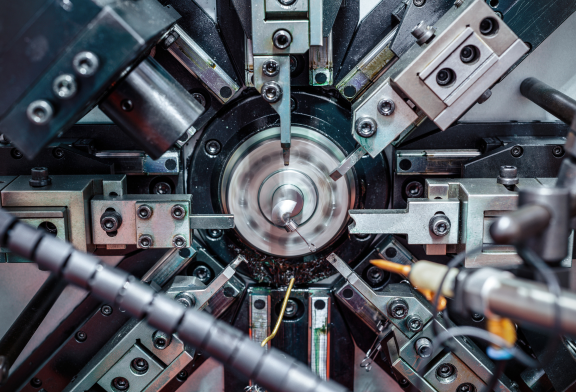

Select the suitable cold forming machine (such as a press or drawing machine) based on the part to be processed, and set up the processing program. Cold forming requires precise machine setup and operation.

Perform processes such as compression, drawing, and bending to form the metal material in a cold state. The goal is to shape the material precisely while ensuring the required product strength and quality.

After forming, perform finishing processes like deburring and surface treatment to ensure the final quality of the part. Surface treatments to improve corrosion resistance and durability are important in this step.

Inspect the finished parts for dimensions, shape, strength, and other specifications to ensure they meet the required standards. Once verified, the parts are delivered to the customer with guaranteed quality.

Developed parts and products are stored on Taiga, making it easy to reprocess (or re-purchase) the same items when needed.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

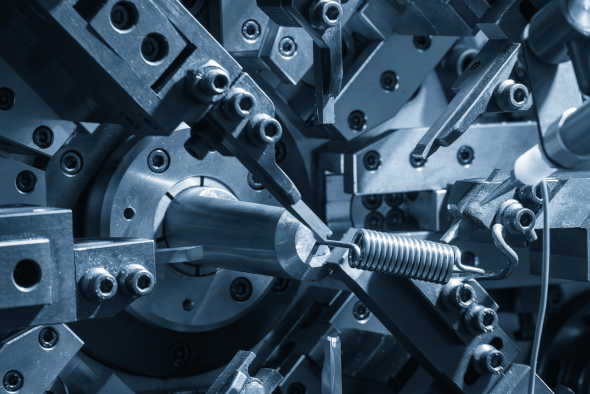

When forming springs through cold working, the bending process is a crucial step. By bending the metal at room temperature, we can precisely shape the ends of the spring or complex forms. Bending is particularly important in spring manufacturing, allowing for fine adjustments to match the required size and shape.

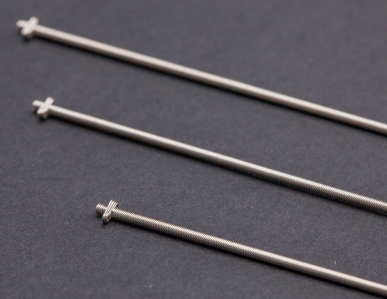

In cold drawing, metal wire is stretched to achieve the desired thickness. By drawing spring steel to the required size and shape, we prepare the basic material for cold working. This step optimizes the spring material and plays a vital role in enhancing strength and elasticity after cold processing.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

We provide comprehensive support for all cold forming processes, from design and material preparation to various shaping, processing, and finishing steps. Additionally, the data of completed parts and products are saved on Taiga, making it easy to reorder with just a single click.

We consistently support high-precision and high-quality manufacturing processes by utilizing the latest equipment and the expertise of our engineers cultivated over many years.

At Taiga, we offer a variety of services designed to achieve more efficient manufacturing.

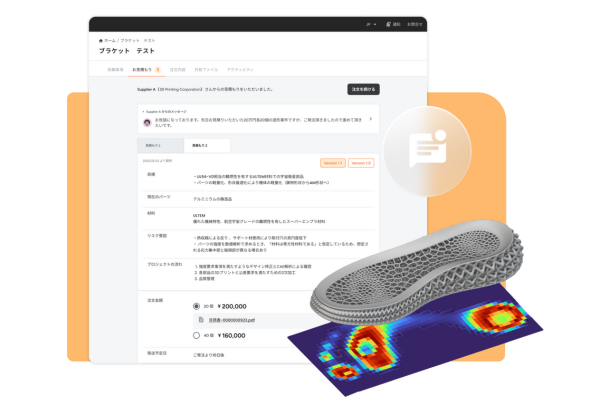

First, we provide a "collaboration feature" that allows all project stakeholders to view and approve drawings and contracts in real-time.

Additionally, our platform enables easy communication through chat, and consolidates various files—such as 2D and 3D drawings, quotes, and project-related documents—into one central location.

These services help meet the diverse needs of our customers, streamline information sharing, and improve efficiency by reducing inspection time, returns, and rework.

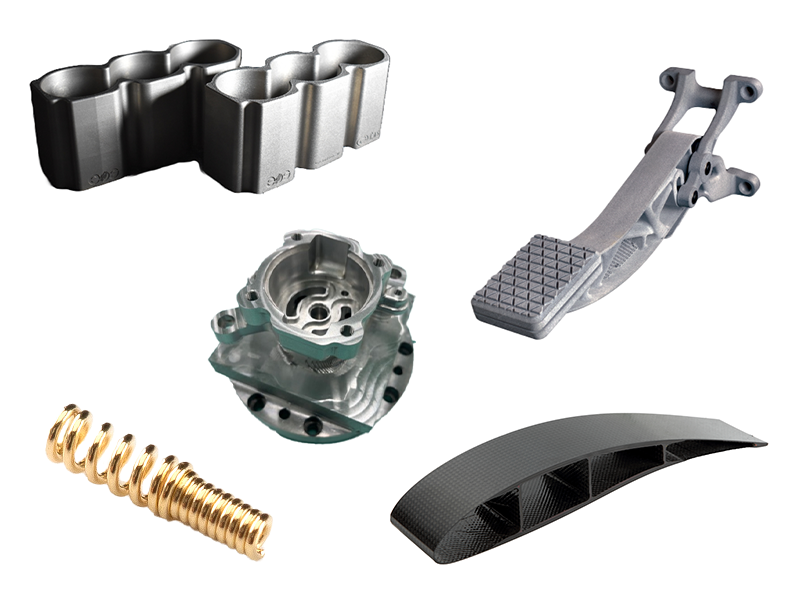

In addition to cold forming, we also support various manufacturing methods such as CFRP processing, sheet metal processing, 3D printing, cutting, and injection molding. We offer multiple options for the manufacturing methods that best suit your product, reducing the hassle of searching for external vendors. This enables quick estimates and smooth parts production.

Sign Up

Contact us to request a registration form, and our team will help you get started.

Upload Your Design

Submit your drawings and project requirements through the platform.

Get Technical Proposals

Receive detailed proposals from multiple companies with advanced technical expertise.

Compare and Collaborate

Use Taiga’s built-in chat and drawing tools to review and discuss proposals with each company.

Place Your Order

Once you’ve chosen the best proposal, place your order directly through Taiga and start production.

No information entry required!

Download >Please feel free to contact us for production consultation!

Contact >

Taiga collaborates with companies that possess advanced processing technologies to deliver the most suitable technical proposals for your needs. Receiving proposals from multiple companies for a single project expands your options and allows you to compare different approaches. By evaluating construction methods, costs, and delivery times, you can choose the most efficient and balanced solution. All participating companies have a proven track record in manufacturing and have built trusted relationships with Taiga’s operator, 3D Printing Corporation, over many years. Our flexible system supports highly specialized technologies, helping to reduce the time and effort required for technical research and vendor selection.

You can view the details of each technology.

Procurement Barrier Looms in Shipbuilding Repairs In shipbuilding repair and refurbishment, procurement of a wide variety of small-volume components and large steel structures frequently [...]...

Alex (Interviewer): Mr. Suzuki, thank you for sitting d [...]

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)

Dear Sir or Madam, We hope that all is well with you at this time. We would like to take this opportunity to thank you for your continued support. We would like to take this opportunity to [...].

In addition to cold working, Taiga can handle all other manufacturing methods.

Our experienced engineers equipped with state-of-the-art technology will propose the best manufacturing method to meet your requirements.