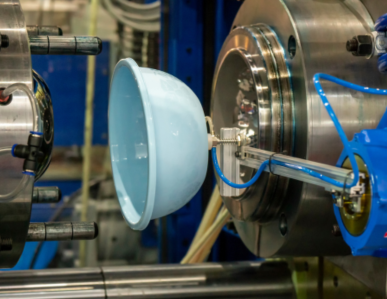

CFRP

CFRP processing is a processing method utilized in automobile manufacturing to reduce weight and increase strength. In particular, CFRP is used for body panels, roofs, doors, hoods, splitters, rear wings, etc. in sports cars and luxury cars, contributing to improved fuel efficiency and driving performance by reducing vehicle weight. CFRP can also be used for structural components such as chassis, monocoque structure, and drive shafts to significantly reduce weight while ensuring rigidity and durability.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)