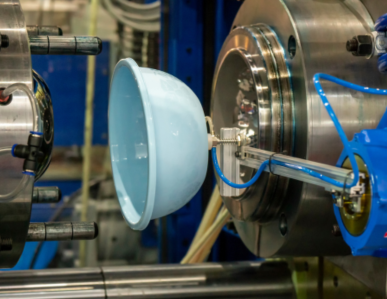

CFRP

CFRP processing technology is gaining attention as a method of manufacturing components that combine lightweight and high strength. In consumer goods, CFRP is used in the manufacture of sporting goods (bicycle frames, golf clubs, tennis rackets), suitcases, smartphone and laptop casings, and design furniture. In addition to being lighter than metal and possessing superior impact resistance and rigidity, CFRP can also achieve a sophisticated appearance.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)