CFRP

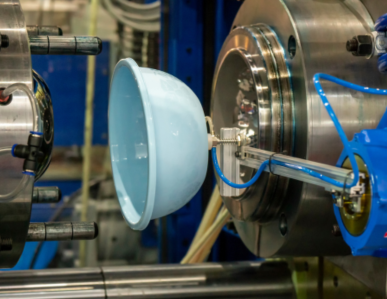

CFRP processing is utilized in the manufacture of prosthetic limbs and orthotics to achieve both lightweight and high strength. In particular, CFRP is used in the manufacture of frames and supports for prosthetic legs and hands, orthopedic braces, and rehabilitation equipment to ensure high durability while reducing the burden on the wearer. CFRP also has excellent corrosion resistance and vibration absorption properties, enabling stable performance over long periods of use and in harsh environments. The high degree of freedom in processing and the ability to design and customize shapes to suit the patient are key features of this material.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)