CFRP

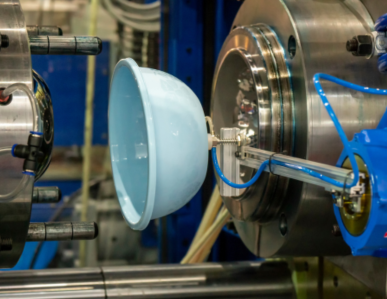

CFRP processing technology is utilized in the field of robotics to realize lightweight and highly rigid structures. In particular, CFRP is used for arms, links of moving parts, and basic frames of industrial robots and cooperative robots, enabling downsizing of drive motors and energy saving by reducing the overall weight of the equipment. CFRP also has excellent vibration damping properties, making it suitable for applications that require precision movements and high-precision control. It is also highly resistant to corrosion and fatigue, and can be considered a material that supports stable long-term operation of robots.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://trytaiga.com/wp-content/uploads/2025/09/Important-notice-300x214.png)